Technology Aims to Trace Sub-Microscopic Troubles

|

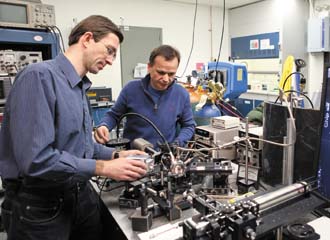

Within the next year, Oak Ridge National Laboratory (ORNL) researchers Nickolay Lavrik (left) and Panos Datskos hope to reduce their bench-scale revolutionary chemical/biological sensor to a handheld instrument. |

Scientists are pushing sensing to the theoretical limit by applying new methodology to established technology. A developmental sensor can help locate and identify chemical, biological and other dangers, but the real breakthrough is the ability to detect nanoscopic amounts of material without requiring sophisticated software or fancy equipment. Instead, humans will be able to see the readings with the naked eye. The advancement means that users in the field will be able to employ the sensor to save lives.

Nickolay Lavrik, research scientist at Oak Ridge National Laboratory, the organization leading the effort, explains that it is difficult to work with tiny objects and substances, such as the ones authorities need to detect at military and airport security checkpoints. The sensor that

Oak Ridge Group Leader and Senior Scientist Panos Datskos explains that when researchers examine sensors or phenomena, they examine the best possible practical and theoretical operations. The ultimate limit of an absolutely perfect system is called the theoretical limit. In the case of the new sensor, the theoretical limit would be one molecule or even smaller. “To detect a single molecule, that’s a big challenge,” Datskos says. “Sometimes we’d like to detect a single molecule either because that molecule is very important or because it’s indicative of something else going on. Imagine being able to detect a single cancer cell.” Entities smaller than a molecule that the system could detect include isotopes. “The point is, can we get there and what is stopping us?” Datskos explains. He continues that the research part of the project is pushing the limit to determine the challenges involved with reaching optimal operation.

The technology itself is a generic approach to sensing using microeletromechanical systems (MEMS) and nanoelectromechanical systems (NEMS), which have been around for more than a decade. “In this particular implementation, it’s basically ... looking at how additional excess mass due to chemical reaction with the sensor changes the property of the sensor,” Datskos explains. “In this case, it’s the resonance frequency of that particular device.” NEMS and MEMS both basically are resonators that oscillate at particular frequencies. Those frequencies shift depending on how many molecules attach to them.

Datskos compares the cantilever in the sensor to a diving board. When someone jumps on it, it resonates at a certain frequency. If weight is added to the board before someone jumps on it, it oscillates at a different frequency. In the sensor, a laser hits the target substance and then bounces back to the cantilever, causing it to vibrate at a certain frequency based on the material of the cantilever and the composition of the target substance. However, these vibrations are so minute that scientists require sophisticated equipment to determine the result.

In general, sensors deal with two effects: sensitivity and selectivity. Regarding sensitivity, the

Users can detect smaller amounts of materials with the new sensor “because a small number of molecules (theoretically only one) is enough to trigger a response,” Datskos says. “In our sensor, this is the result of the nonlinear behavior and the large amplitude of oscillation.” The

The researchers have found a way to take advantage of the distortion so that, as far as the sensor is concerned, the response is linear even though it is operated in a nonlinear regime. Even more important from the practical point of view is that this effect can be seen with the naked eye instead of laboratory equipment. Lavrik explains that the phenomenon observed is called amplitude collapse. “That’s a very dramatic effect,” he says.

In a typical sensor in a laboratory environment, the measurement accuracy of the oscillation of the cantilever can be as small as a few atoms. When traditional resonators that operate at nanometer-scale amplitudes are used, this accuracy is difficult to achieve because of noise. With the higher oscillation amplitudes, the projection line created by the oscillating beam in the new sensor measures as large as an inch. When this amplitude collapses, that line shrinks to a dot. When that happens, users know how many molecules were added to the cantilever of the device.

|

This silicon chip with nonlinear resonators mounted on the piezoelectric transducer in the flow cell is part of the setup of a new sensor that scientists at ORNL are developing. |

In terms of applications, the sensor could detect all sorts of materials including physical, biological and chemical substances by using different materials in the construction of the physical device. By changing the surface layer or coating in the sensor, it can be used for different purposes. Datskos says it could even sense acoustics and temperature. “The cantilever platform is very generic,” he says, adding that, “It’s a tool that’s very versatile and unique. It’s a universal platform really.”

In addition to public security applications, people could employ the new sensor technology in their homes and cars. One device could detect smoke and carbon monoxide, reducing the current need to have two devices, one to detect each substance. In automobiles, the sensor could indicate a problem in the exhaust or combustion. Instead of requiring motorists to have an inspection once a year to check emissions, the sensor could provide constant monitoring. The issue is that all these applications involve cost. Datskos says if it only cost a few cents, every car would have one. But in reality, it would add a significant amount to the price.

The laboratory prototype of the sensor is geared toward chemical sensing of items such as explosives. “A lot of that is funding driven,” Datskos shares. “Basically, the funding comes from a need, either a national need to address something or it could be an energy need or a national security need or science needs.” Those funding requirements guide the researchers’ specific efforts. “It’s not like two mad scientists working in a laboratory and doing it all,” Datskos jokes. “There’s a real world we have to consider.”

As a laboratory,

He compares the sensor to the CD player. When it first was developed, it worked in the laboratory but not in the real world because of vibrations. “Now it works in your car; it works anywhere,” Datskos says. Manufacturers found a way to package the technology so it would operate in the field, and they were able to mass produce the technology.

Moving a prototype to a commercial product requires a high level of investment in part because the technology has to become easy for lay people to use. “The idea is experts could use this, but you also want nonexperts to turn the knob and say ‘Yes, it works. [Or] it doesn’t work,’” Datskos explains. Developers have to find a way to package the devices so anyone can use them, just as they did with CD and DVD technology. However, he also believes the hardest part of the work already is complete. “The most difficult thing is it’s an idea which has been implemented,” he says. “It works and that it essentially can be used.”

Once the initial investment has been made, however, further production of this sensor should be less expensive than other similar devices. “In the long run it will be cost-effective plus it will enable detection limits not possible before with traditional techniques,” Datskos explains. The new sensor especially can improve operations in noisy environments where the vibrations can affect traditional sensors and wash out signals.

Though the

Again, those next steps depend on money. To continue pushing the science forward requires more research dollars. “Development funding could keep going to develop this particular sensor from this stage on,” Datskos explains. However, as a scientist, his thrust is not only to use similar approaches in different ways but also to develop new approaches to traditional methods and tools.

Lavrik echoes his research mate, saying that they can continue to explore different aspects of this type of sensing phenomena, pushing the limits of what is possible. But a technology transfer of what they already have discovered will depend on funding from a company or an agency interested in particular applications of the idea.

WEB RESOURCE

Comments