Army Robots Gain Real-World Testbed

Robots trying out to become part of the U.S. Army’s battlefield force now have their own real-world testbed built atop what used to be a nerve gas testing site. The Army Research Laboratory has built the Robotics Research Collaboration Campus, or R2C2, in Graces Quarters at the Aberdeen Proving Ground in Maryland. Formerly a superfund site, the area now is sprouting buildings amid mixed wooded and grassy terrain typical of what the Army may find on future battlefields.

The campus will provide the laboratory with areas to test individual robotic technologies along with finished vehicles. Robots under development can be evaluated for specific functions before their design is finalized. Similarly, specific aspects of robotic technology can be trialed during a robot’s development before being outfitted on vehicles. Researchers also can use the testbed to explore ways of linking airborne robots with vehicular counterparts in the field. Ultimately, researchers will test and evaluate future Army concepts that involve robots.

What sets this site apart from other field testbeds is its location in the national capital region. Instead of journeying long distances with relevant hardware to evaluate just one aspect of robotic capability, Army Research Laboratory (ARL) researchers and their partners can assess the results of their research locally in real time.

“It is more than a laboratory. It’s an exploratory robotics proving ground,” declares Jaret Riddick, director, Vehicle Technology Directorate, Combat Capabilities Development Command (CCDC) ARL. “It can serve the role of being a technology incubator.”

The new facility will give these researchers the ability to rapidly test laboratory developments, says David Baran, branch chief of the Intelligence for Robotics Branch at the ARL. He explains that the testbed will allow researchers to validate basic algorithms through real-world experiences. Simulations now can be confirmed by field tests in a controlled environment that is much closer to actual battlefield conditions.

Geoffrey Slipher, chief, Autonomous Systems Division, ARL, relates that much of the ARL core research staff and key collaborators are located in the national capital region. While the ARL uses other Army and service sites across the nation, having this local facility makes “breaking algorithms and fixing them” much easier to carry out.

He continues that much of the code provided by ARL partners, particularly those from academia exploring the cutting edge, is “extremely brittle.” It tends to work in a handful of environments, but outside of those, breakdowns are common. This is not unusual for early algorithms for autonomous operations, he adds. Repeated cycles are necessary for breaking down the code and fixing it for field operations, which requires a high operational tempo. Having a local facility for these cycles speeds up the technology development process.

“Imagine the amount of curated data that we’ll be able to produce in a controlled environment that we have access to for collaboration,” Riddick suggests. “And data is worth its weight in gold to a researcher.”

The 5-square-kilometer facility also is located in proximity to the Army test and evaluation community at Aberdeen. The ARL is engaged in conversations with the community for phased robotics testing at the R2C2.

Baran notes that the R2C2 is not completely in line with a full battlefield environment. It does not offer the scale of an actual military battlespace where operational areas are measured in many kilometers. Similarly, the area does not offer every potential type of environment the Army might face. It has no desert, for example.

But its open fields, woods, rolling terrain and marshy areas offer a spread for evaluating vehicle mobility and versatility, he continues. Aspects of those field characteristics can allow researchers to evaluate specific robotic functions. Baran relates that the Army’s focus on robotic navigation currently is on wooded terrain and hills.

The wooded terrain offers many potential variables. Baran describes it as having a lot of undulation, ranging from slight slopes to ravines. Being on a peninsula, it offers a number of challenges for robot sensors—for example, being able to discriminate between a puddle and a leak.

The ARL is building a small village based on CONEX shipping containers in a large open area. The modularity of these constructs allows the laboratory to modify or expand the village to introduce more complex conditions. This will provide a limited urban warfare capability, which will be more important for some of the laboratory’s far-reaching research, Baran says. Experimenters will be able to introduce hazards such as barriers across a roadway that would force a robot to reroute its path during movement. Researchers even could set up a test for a robot to differentiate between an artificial obstacle left by an adversary and a natural one such as a fallen tree branch.

“We have this local environment that is easy to access where we have full control over the configuration of the facility,” Baran says. “So, if one of my researchers tomorrow says, ‘It would be really cool if we could test this new algorithm in a street scene that had roadblocks [in specific locations] with a 2-meter gap in between the two buildings on the left side of the road,’ in a matter of a couple of weeks, we can construct that environment and be able to go and try it for real. We don’t have to schedule range time months in advance; we don’t have to share the facility with others who might be needing to use the same spaces. It really allows us to hit the rapid test.”

The R2C2 will have some robotics laboratory facilities on site. This will allow ARL researchers and academic partners to come in for testing on the range, after which they could tweak algorithms and return to the range in real time.

These partners, along with ARL small business partners, will be able to work hand-in-hand with their ARL counterparts to test the outcomes of their research. Baran notes that a new program, Scalable, Adaptive, and Resilient Autonomy, is taking shape. It’s testing schedule with research partners likely will be determined by COVID-19 concerns, he admits.

The facility also is spawning a major change in the research and development regimen. When completed, a version of the village and its surrounding terrain will be incorporated into the laboratory’s robotics simulations. This way, researchers will have a physical instantiation of a larger scenario that can be validated in the real-world range.

Most of the testing foreseen for the near future is likely to focus on evaluating individual components and capabilities, rather than battle-ready robots, Baran offers. In the near term, the capability that is most likely to be evaluated at the R2C2 is navigation, he suggests. Virtually the entire spectrum of autonomy for robotics will be fair game for the campus.

For example, researchers are working on autonomous navigation over a large field. Most related capabilities have been designed for the short distances available in a parking lot. Now, the researchers can introduce kilometer-range capabilities into the simulation environment. Once that lab testing is completed, it would be introduced into a robot for limited field testing at an existing laboratory. After that, the navigation capability and its vehicle would be taken to the R2C2 for evaluation over the field terrain.

Subsequently, the ARL would work with some of its other partners to increase the testing complexity and evaluate it on larger systems, Baran says. This represents a move away from experimental algorithm assessment toward full capabilities in end-to-end systems.

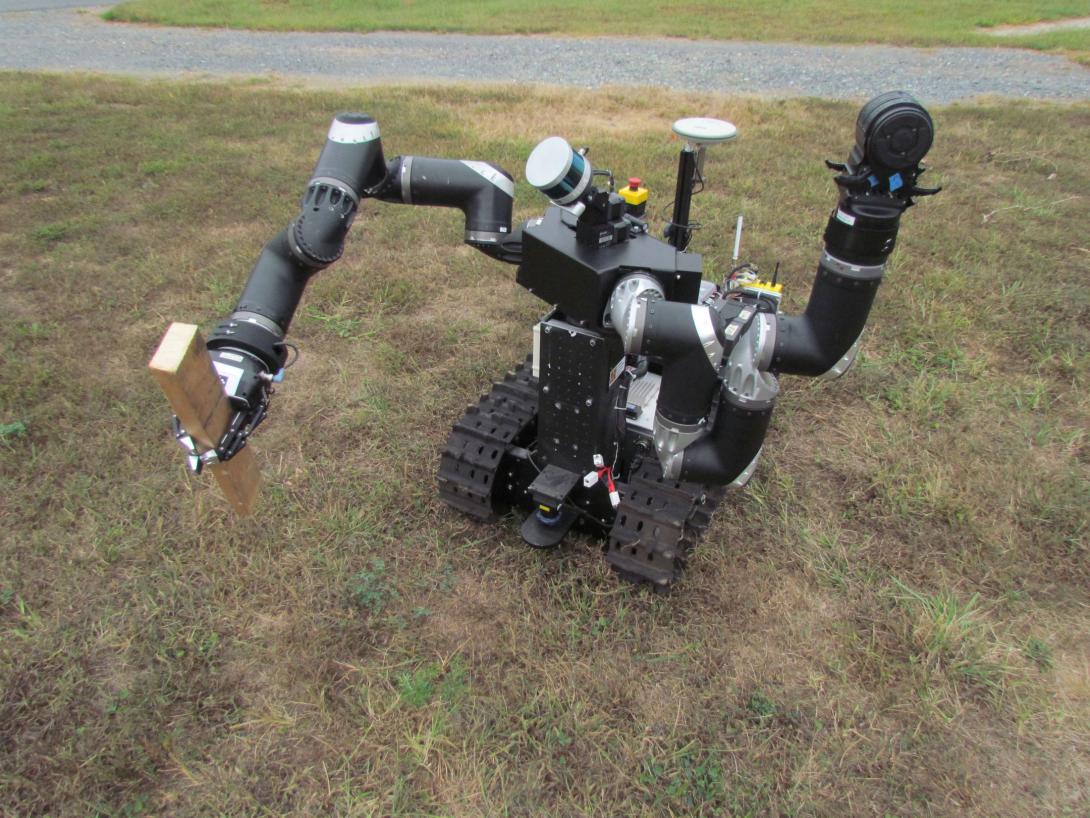

Ground vehicles are not the only robots the ARL will test at the R2C2. Slipher reports that the original focus will be on small unmanned systems as surrogate platforms, on which will be tested algorithms that can confer autonomy on others. These unmanned systems will weigh 20 pounds or less, and they will comprise fixed-wing, quad-rotor and hybrid platforms, which would offer extended range and endurance along with the flexibility of hovering and perching.

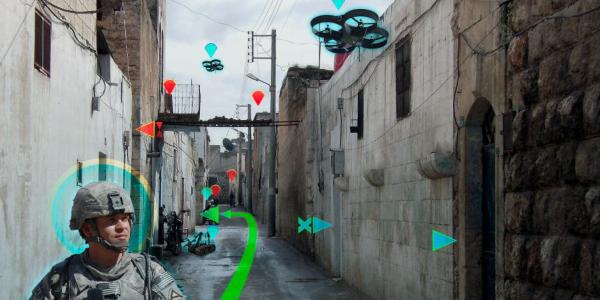

A key aspect of these airborne robotic vehicles would be to coordinate them with ground vehicles, he adds. Researchers want to determine how these two categories of vehicles would interact, both autonomously and with human command and control (C2). “Could a human command a team of heterogeneous robotic systems to go out and perform a mission, and that team then allocates which platforms do what based on their capabilities and the changing circumstances,” he offers as one area of research.

Other possible combinations will be explored, such as having one ground platform with multiple air platforms, he continues. The ARL is examining whether ground platforms can provide added endurance for their airborne counterparts by allowing them to land autonomously and recharge, for example.

The R2C2 itself will not change greatly as a real-world testbed. Baran allows that, over time, the village environment will be expanded with increased complexity. The evolution of the facility largely will depend on the evolution of the robots being tested.

The location’s history as a superfund site did play into the ARL’s adoption of it as a testbed, Riddick allows. The area was kept apart from development that went on in the region, which made it ideal as an unused area well-suited for real-world field testing. In establishing the R2C2, the Army took an environmental-friendly approach. The ARL conducted extensive environmental assessments of the area, which consists of a small peninsula jutting out into Dundee Creek and the Gunpowder River. Slipher relates that the laboratory went through a long process to comply with the National Environmental Policy Act, including planned operations and public notices and comments.

“The environmental assessment was paramount in our gaining access [to the site],” Riddick declares.

Slipher notes that the area has been used by the Army, and one recent tenant that finished its work four years ago left an infrastructure that the ARL was able to modify to suit its purposes. This includes a high-bay building with rollup doors that is being adapted to robotic experimentation needs, and it is part of the laboratory’s four-phase development plan for the site.

The first phase entails establishing the basics for operation as a scientific testbed, including a staff presence. The second phase will upgrade the site as well as lay the groundwork for future development. Researchers have provided input on new site features that will help them use the facility more effectively.

One key site feature will be edge data processing and storage, Slipher reports. As the site matures, researchers may be testing dozens of robots simultaneously. Even though the site will have high-bandwidth links back to the proving ground and its high-performance computing system, this connectivity is not nearly enough to provide a data stream in real time, which could be substantial.

Another upgrade will be to increase the number of robotic external assets there, he continues, along with ramping up experimentation. Phase three will tap this expertise to add more advanced experimental capabilities, while phase 4 will build on these efforts.

Riddick emphasizes that the communications and computing capabilities are not limited to the R2C2 site. The location is networked to other ARL facilities as well as partner locations. While this will allow rapid data exchange, it also will open up the R2C2 to an important aspect of future Army robotic operations.

A networked C2 capability will allow distributed C2 experimentation for future robotic systems. One issue facing Army planners is how to command and control an autonomous system from great distances. This will require data feedback from the robot to headquarters, potentially amid bandwidth limitations imposed by an enemy. These questions and other related challenges, such as how humans will interact with these robots, can be confronted through both simulation and hard experimentation, Riddick offers.

Work on the facility has been slowed by the coronavirus pandemic, but ARL researchers hope it will be operating this summer. Planners aim to have Phase 2 complete within 12 months of initial experimentation, with Phase 3 to follow one year later.

Comments