Bye-Bye Lithium-ion Batteries?

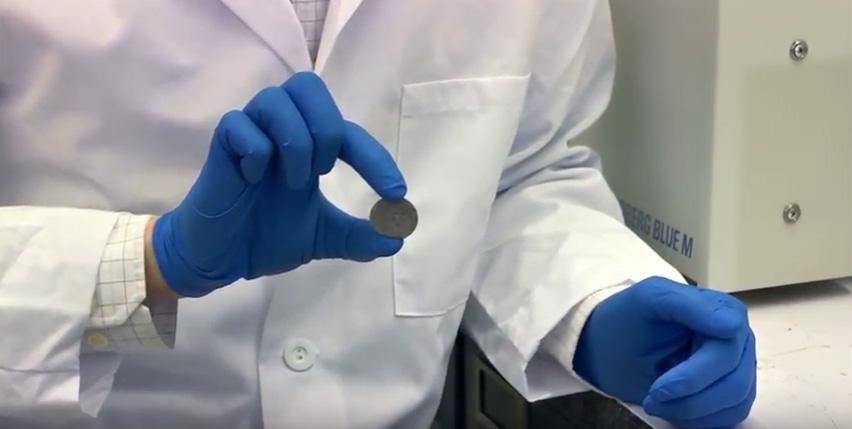

Researchers at the U.S. Naval Research Laboratory’s (NRL) Chemistry Division developed a 3-D zinc “sponge” architecture that will extend the life of the cells in today's single-use batteries and provide a safer alternative to fire-prone lithium-ion batteries, officials announced Thursday.

Researchers swapped in this new 3-D sponge to produce fully rechargeable nickel–zinc prototype cells, a breakthrough that challenges lithium-ion performance in terms of power, and certainly, safety, they said. The patent-pending electrode allows for rechargeability and performance that researchers said is on par with lithium, improving not only safety but also size, weight and availability.

Lithium-ion batteries have been implicated in two fatal plane crashes since 2010, and as of March 27, the FAA has reported that 152 aviation incidents since 1991 have involved lithium batteries carried as cargo or baggage that involved smoke or fires. Also, the Navy has banned some products that use the batteries, including electronic cigarettes, on ships, submarines, aircraft and other platforms because of fire worries.

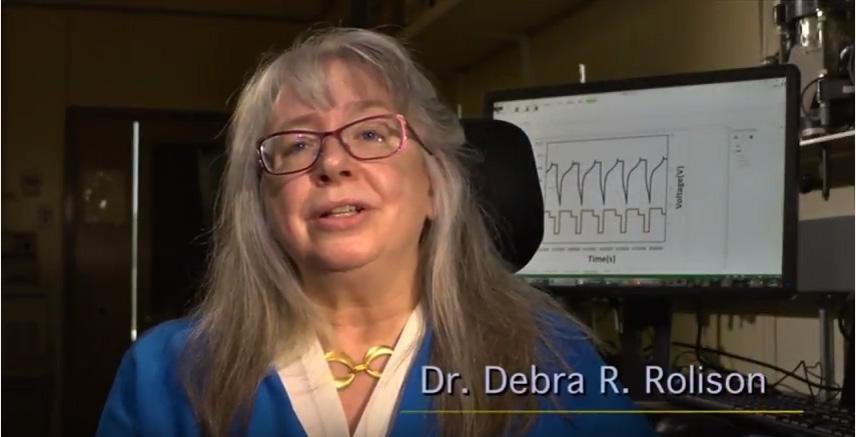

Lithium-ion safety concerns expressed by military leadership, in part, spearheaded the NRL’s work, said Debra Rolison, who heads the Advanced Electrochemical Materials section at the NRL in Washington, D.C.

“This is pretty much a breakthrough for battery design that enables us to make simpler, less complex systems, particularly for military applications,” added Michael Burz, president and CEO of EnZinc, which partnered with the NRL and garnered a limited use license for commercial application and use. The new architecture offers the energy of lithium-ion batteries, but at a cost closer to lead acid batteries, Burz said.

Manufacturers will be able to tailor future batteries to just about any shape and any application, experts shared during a news media teleconference Thursday. “Because we’re creating the 3-D zinc from a zinc emulsion, manufacturers can make it any form factor they want,” Rolison said. “We can work with it small, we can work with it large, we can work with it stacked. You should be able to use this from micropower to consumer electronics to vehicle to grid.”

The team of industry and government researchers now will embark on an expected two-year cycle to test storage, packaging, scalability, environmental effects and power-accelerated stress, Burz said. “We feel we can have a battery ready for the market by the end of 2019.”

While it still is a little too early to offer precise cost savings, Burz predicts total system costs for an electric vehicle equipped with the 3-D zinc batteries, for example, will be 30 percent to 50 percent cheaper than a comparable lithium-ion system.

“What excites us is the elegance and simplicity of the zinc structure that makes it available to a family of zinc-based batteries that are … cheaper, safer [and] recyclable and using an abundant material,” Burz said. There is no shortage of zinc supply. It is the fourth-most mined material on the planet, with more than 14 million tons mined a year, Burz shared. “We calculated that to supply a million electric vehicles … we’d only use 2 percent of the available zinc in the world. Using this kind of material, we are taking a look at American energy independence and kind of weaning ourselves off of Middle East oil. We don’t want to trade our American energy independence by trading oil for lithium, which is mined in other countries. We can take care of that here in the United States.”

With the benefits of rechargeability, the 3-D zinc sponge can change the civilian and military power needs landscape, said Jeffrey Long, a staff scientist at the NRL. “We can now offer an energy-relevant alternative, from drop-in replacements for lithium-ion to new opportunities in portable and wearable power, and manned and unmanned electric vehicles, while reducing safety hazards, easing transportation restrictions and using earth-abundant materials.”

Rolison, the principal investigator on the project, said, “Our team at the NRL pioneered the architectural approach to the redesign of electrodes for next-generation energy storage. The 3-D sponge form factor allows us to reimagine zinc, a well-known battery material, for the 21st century.”

Additionally, the NRL-based team will study silver-zinc applications, which might be able to provide “power that we haven't even seen with lithium-ion,” Rolison said. “That could be an extreme interest to the Navy for some of the submersible applications.” While silver-zinc has been used by the Navy for a long time, current solutions do not have battery rechargeability features.

The NRL’s work is funded by the Office of Naval Research and the Advanced Research Projects Agency-Energy. The team’s research will be published in the April 28 issue of Science, the weekly-published journal of the American Association for the Advancement of Science. Contributors to the research article in Science, which is peer-reviewed, include Christopher Chervin, a former NRL staff scientist and Irina Pala, a postdoctoral associate at the National Research Council.

Comments