This Itsy Bitsy Spider is a Robot

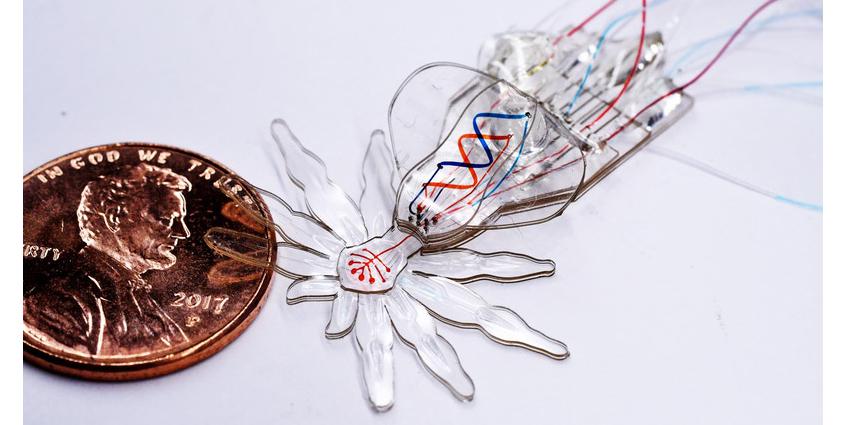

Researchers have developed an integrated fabrication process that for the very first time enables the design of soft robots on the millimeter scale with micrometer-scale features. To demonstrate the capabilities of their new technology, they created a robotic soft spider from a single elastic material with body-shaping, motion and color features.

The research team members are from Harvard University's Wyss Institute for Biologically Inspired Engineering, Harvard John A. Paulson School of Engineering and Applied Sciences, and Boston University. The study is published in Advanced Materials.

“The smallest soft robotic systems still tend to be very simple, with usually only one degree of freedom, which means that they can only actuate one particular change in shape or type of movement,” says Sheila Russo, Ph.D., co-author of the study, in an announcement from Wyss Institute. “By developing a new hybrid technology that merges three different fabrication techniques, we created a soft robotic spider made only of silicone rubber with 18 degrees of freedom, encompassing changes in structure, motion, and color, and with tiny features in the micrometer range.”

The team first used a soft lithography technique to generate 12 layers of an elastic silicone that together constitute the soft spider’s material basis. Each layer is precisely cut out of a mold with a laser-micromachining technique, and then bonded to the one below to create the rough 3-D structure of the soft spider.

The approach, known as Microfluidic Origami for Reconfigurable Pneumatic/Hydraulic (MORPH), could open up the field of soft robotics to researchers who are more focused on medical applications where the smaller sizes and flexibility of these robots could enable an entirely new approach to endoscopy and microsurgery, researchers say.

Roboticists envision a future in which soft, animal-inspired robots can be safely deployed in difficult-to-access environments, such as inside the human body or in spaces that are too dangerous for humans to work, in which rigid robots cannot currently be used.

The U.S. military also has shown interest in soft robots. Army Research Lab scientists announced last month that they have created 3D printed robotic structures can squeeze in tight spaces such as a crack in the wall of a cave, jump over trip wire or crawl under a vehicle—all complex Army-relevant functions impossible for humans to perform safely.

The approach developed by the Army's Institute for Soldier Nanotechnologies located at MIT uses a 3D printing platform fitted with an electromagnet nozzle and a new type of 3D printable ink infused with magnetic particles. The findings could lead to new biomedical applications, magnetic ink optimized to strengthen soft robotic functionality and new on-demand flexible material systems for integration into soldier systems.

Soft robotic capabilities and manufacturing at the point of need are among the Army's top research priorities.

Comment

Are there cameras or audio

Are there cameras or audio recorders on these nano technologies?

Comments