Smart Fasteners Transform Assembly and Upkeep

Editor's Note: Since the publication of this article Intevia has been acquired by its partner company Telezygology Incorporated (tzinc.com).

|

| Intelligent fastening technology will allow maintenance personnel equipped with wireless devices to unfasten remotely avionics and other mission-critical electronics panels in aircraft, ships and ground vehicles. Sensors embedded in the fasteners permit the monitoring of electronics cabinets, reduce weight and support a lock–unlock capability for security and maintenance. |

A new class of mechanical devices with embedded electronics will allow personnel to access maintenance panels and equipment in aircraft and other platforms rapidly and without the use of tools. The technology permits the remote closing, locking and unlocking of fasteners via wireless handheld devices. The fasteners also are equipped with sensors to report their status and that of the structures immediately surrounding them, offering the potential for smart logistics and vehicle diagnostic systems.

The Intevia intelligent fastener technology developed by Acument Global Technologies Incorporated, Troy, Michigan, consists of a line of mechanisms ranging from low- and medium-load-bearing devices for locking cabinets and access panels to high-load-bearing fasteners for structural panels. John Wilson, chief operating officer, Telezygology Incorporated, a Chicago-based design firm working with Acument, explains that the technology has applications in four areas: rapid assembly, rapid reconfiguration, increased security and enhanced access control.

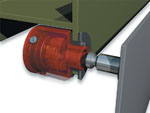

Each fastener is a mechanical device consisting of a pin or socket that locks into a male or female part and an actuator that releases the device.

A battery source or a vehicle’s electrical system provides the current to activate the actuator. This electrical energy is switched by a field effect transistor that manages the amount of power applied to the actuator. A micro controller built into each device’s circuit board enables power transfer and remote control of the fastener, says Geoffrey Sizer, Telezygology’s general manager of technology.

Several methods are used to communicate with the devices. The simplest method uses electrical contact closures that sense input. One example of this type of mechanism is a push button or relay from another system that activates the fastener. More sophisticated versions of the fastener can be activated by a communications protocol packet sent over a vehicle network or an industrial computer network. By adding a communications interface device, Sizer notes that commands can be sent wirelessly from a key fob or via Bluetooth or ZigBee wireless technology using a personal digital assistant or desktop computer.

Each Intevia fastener has a sensor built into it. The sensor records whether the device is closed or open and whether it is attached to or detached from its retained mating stud, which is the element that couples to the fasteners. The sensor also monitors temperature and power supply. By adding sensing elements connected to auxiliary inputs, users can monitor other functions such as stress and strain, movement, acceleration or the presence of certain gases. In addition, a sensor system may feature auxiliary outputs that can operate electrical circuits if needed. Sizer says that the technology provides fastening, control, sensing, status reporting and auxiliary control functions in a single package.

Products are assembled in a factory then disassembled for service, repair or maintenance,

Most maintenance relies on people,

|

| Defense manufacturers are interested in intelligent fastening mechanisms for the remote opening, closing and locking of bay doors in a variety of aircraft applications. |

Computerizing assembly and maintenance processes allows the creation of service logs and permits authorized access and control of sensitive equipment.

Because the fasteners can be unfastened remotely, an aircraft technician could use a personal digital assistant to open access panels without having to spend time manually loosening fasteners. Besides the convenience of speed, the devices provide security. Sizer points out that the fasteners can be programmed so that only an authorized technician at an authorized location could open certain panels. Wireless communications to the fasteners can be encrypted, and the system can be set to permit only certain personnel to access sensitive areas. “This is very important to the aircraft industry from an anti-terrorism point of view. It ensures that no compartments can be accessed during maintenance without being logged because of the potential for a bomb being stowed in an electronic equipment bay,” he says.

Intelligent fasteners do not require additional space for access by handheld tools, which could have a revolutionary impact on design, Sizer adds. “In an automobile, if you don’t need to get a wrench or a screwdriver into any particular area because you have enabled it with intelligent fastening, there is a scope for fairly dramatic changes in terms of size and weight in a vehicle,” he says.

The fasteners also can provide predictive maintenance. When a component is damaged, worn or reaching the end of its service life, it automatically can notify maintenance personnel that it must be replaced. Sizer explains that this ability to predict when parts need replacement extends beyond the fasteners, which can be equipped with other sensors to monitor the platform around them. For example, a structural element can be outfitted with a strain gauge to measure load cycling or temperature. “By having an intelligent sensor network throughout an aircraft sense all sorts of parameters relating to its health, they [the sensors] could detect abnormal operation that may lead to a fire and movement, stress or strain leading to a structural failure,” he says.

For military applications, Sizer notes that a future military vehicle that has received battle damage could go to a depot where its smart communications network could self-diagnose the extent of the damage and automatically order the needed spare parts. “The vehicle could literally drive in, have the parts removed and replaced—perhaps in a matter of minutes—and be back in combat service,’’ he shares.

The use of shape memory metal alloy actuators allows Intevia to produce mechanisms that are much smaller and lighter as well as more power-efficient and effective than competing technologies such as solenoids and motors, Sizer says. In addition to being more cost-effective in a range of applications, coupling the fasteners with electronics results in more sophisticated mechanisms, he adds.

Fasteners are a fundamental part of any vehicle; therefore, they should be incorporated in a design from the beginning to be a fully functional part of a platform.

Acument’s intelligent fastener technology was introduced to the aerospace market in 2005 and to the automotive industry and industrial sector in 2006. The design of business jet cabins, which often are highly customized by their owners, is another area where the fasteners could have applications,

Web Resources

Acument Global Technologies Incorporated: www.textronfasteningsystems.com

Telezygology Incorporated: www.tzinc.com

Comments