Tiny Tubes Trumpet New Possibilities

|

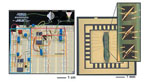

| Researchers at Northrop Grumman and the University of Illinois have built a transistor radio with key components made from carbon nanotubes. The radio was built to demonstrate new techniques for growing parallel rows of nanotubes, which allows the structures to be readily adapted for use in a range of electronic devices. |

Nanotechnology may soon provide warfighters with lightweight and powerful electronic equipment. Researchers have created a fully functional transistor radio made entirely of carbon nanotubes. This feat demonstrates that these microscopic structures can be used as high-speed transistors and radio system components that consume only a fraction of the power required by current equipment.

The radio was designed and built by a team of scientists from Northrop Grumman Corporation and the

Carbon nanotubes are cylindrical structures composed of carbon molecules. These structures can be up to several millimeters long with a diameter of several nanometers—approximately 1/50,000th of the width of a human hair. There are two varieties of nanotubes, single-walled nanotubes (SWNTs) and multi-walled nanotubes. Despite their tiny size, carbon nanotubes are among the strongest and stiffest materials on Earth. Nanotubes also can move electrical current with little or no resistance, and they are efficient heat conductors and insulators. It is this range of properties that attracted Northrop Grumman researchers to find new methods to build electrical components, says Przybysz.

Although scientists have known about carbon nanotubes since the 1970s, nanotubes’ potential for electronics was not fully understood until the 1990s. Nanotubes, primarily SWNTs, have been used in a variety of prototype systems such as microprocessors and “lab-on-a-chip” devices designed to detect biological and chemical agents (SIGNAL, December 2006). However, industrially manufacturing nanotubes is still not practical because it is difficult to consistently control the proportions and electrical properties of individual tubes.

By making a radio from SWNTs, Northrop Grumman and University of Illinois scientists have developed methods to create radio frequency (RF) nanotube analog electronics such as narrowband amplifiers that can operate in very high frequency bands with power gains as high as 14 decibels. The team built tiny transistor radios with SWNT devices performing all key operations such as resonant antennas, fixed RF amplifiers, RF mixers and audio amplifiers. According to a paper published in the Proceedings of the National Academy of Sciences, the experiment represents an important first step to the practical implementation of SWNTs in high-speed electronic circuits.

When researchers began studying electronics applications for nanotubes, Przybysz notes that many scientists assumed the structures were too small and hard to produce for practical applications. This viewpoint changed with the development of new techniques capable of manufacturing large batches of tubes. “When we got our hands on some transistors that had thousands of tubes instead of one, we knew we had enough semiconductor [material] to do some real work. Building a radio was the way to demonstrate that this isn’t just a laboratory curiosity; it can be a real function,” he says.

The key advance allowing researchers to build the tiny transistors is the ability to grow carbon nanotubes in parallel rows. This is extremely difficult under conventional vapor deposition methods because the tubes are likely to grow haphazardly, which greatly reduces their electrical properties. Przybysz explains that

Although the transistors and main components of the prototype radio are invisible to the unaided eye, the major features of the device are made with off-the-shelf equipment. Przybysz explains that the experimental radio has a large battery and a makeshift antenna wrapped around a roll of tape. The radio is built onto an electrical breadboard with wires, capacitors and resistors plugged into the structure.

Because they are made of carbon, nanotubes are resistant to high temperatures. In conventional electronics, heat will either destroy a device or cause it to stop working. When a silicon semiconductor or transistor stops functioning, it may be permanently inoperable or it may require only cooling off before resuming operation.

Another quality of carbon nanotubes is their ruggedness. They are not as sensitive to heat and dust as conventional semiconductors. The transistors in the radio are not sealed, yet they remain functional after being exposed to the open air in the laboratory for more than a year. Przybysz notes that conventional semiconductors would not function after such exposure. “Carbon nanotubes are tough,” he says.

When Thomas Edison invented the light bulb, Przybysz relates, the first prototype filaments were made of carbon before they were replaced with less expensive tungsten. Carbon initially was chosen because of its durability—it could be heated repeatedly to white-hot temperatures without damage. Carbon nanotubes appear to have a similar level of toughness to them, but he cautions that it is still not known how much they can take before failing.

Another area where carbon nanotube-based technologies may make their mark is in handheld communications systems. “A problem soldiers face is having to choose between carrying batteries and carrying bullets. Our hope is to let them carry more bullets and less batteries,” Przybysz says.

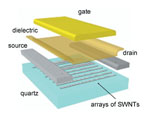

|

| The core technology of the nanotube radio is the ability to grow parallel arrays of tubes on a quartz substrate. The electrical and thermal properties of nanotubes open the potential for highly power efficient and compact electronic equipment. |

The company-university partnership began its carbon nanotube research in 2004. Przybysz notes that promising nanotube research at other company, university and government laboratories persuaded Northrop Grumman to launch its own nanoscale electronics program.

The thermal and electrical properties of nanotubes make them ideal for high-speed transistors, says Dr. Hong Zhang, Northrop Grumman’s lead for carbon nanotube development. Nanotubes can form more efficient, scalable circuits capable of amplifying analog signals at much lower power rates than conventional semiconductor devices made from silicon or gallium arsenide, she says.

Researchers are using nanotubes in biological and chemical weapons detectors and as components such as analog amplifiers, microwave amplifiers and analog electronics. In electronics applications, Przybysz estimates that carbon nanotube transistors will operate in the terahertz range with cutoff frequencies at between 3- to 30- terahertz. Nanotube devices also can be incorporated into conventional microprocessors. “That opens up a lot of spectrum and potential uses. You can make a very low power amplifier with a device made from these semiconductors,” he shares.

Now that a working nanotube radio has been built, Przybysz says the next step is to develop higher-frequency devices that use less power. The radio was built in February 2007 and tested for much of the year.

While researchers have made nanotubes in the laboratory for many years, producing them in industrial quantities remains a major challenge. Przybysz notes that no one currently has a process capable of making large quantities of uniform, reproducible, high-yield carbon nanotubes. “That’s not available anywhere that we know of,” he says.

Northrop Grumman currently is developing an industrialized carbon nanotube production capability, but the process still is being perfected, says Zhang. Przybysz believes that the company currently has the best industrial-grade carbon nanotube production method. “It’s not cheap, but it works,” he says.

Carbon nanotubes are made in a chemical vapor deposition process similar to that of microchips, with graphite laid down at the atomic level. Nanotubes are produced under pressure with iron nanoparticles often used to seed the growth. Large irregular arrays of carbon nanotubes can be grown on silicon wafer substrates. Because the semiconductor industry is constantly developing new methods and tools to make better microchips, Przybysz explains that Northrop Grumman researchers do not have to develop their own deposition systems. “We’re riding the back of the whole semiconductor industry here,” he admits.

Przybysz notes that the entire field of electronics is potentially open to carbon nanotube applications. However, he adds that it remains an engineering tradeoff as to whether or not nanotubes will entirely replace or complement other semiconductors. The structures can be used in a variety of devices such as low-power front ends for receivers. “The rule for transistors is the smaller they are made, the faster they run. All our current research is to make it smaller, make it faster,” he maintains.

Web Resources

Northrop Grumman: www.northropgrumman.com

Proceedings of the National Academy of Sciences: www.pnas.org

Comments