Researchers Advance Liquid Metals for Futuristic Electronics

A collaborative, multidisciplinary team of U.S. Air Force Research Laboratory (AFRL) researchers recently demonstrated that nontoxic liquid metals can create multifunctional, reconfigurable electronics and flexible power connections for nontraditional electronics. The advance may help lead to self-healing electronics, shape-shifting antennas and clothing woven with conductive threads to electronically connect devices.

Christopher Tabor, a research scientist in the nanoelectronics branch of AFRL’s Materials and Manufacturing Directorate, and his team demonstrated that liquid metal alloys could be flowed through channels embedded in structural aerospace components. The result: physically reconfigurable electronic material able to change antenna and electrical circuit characteristics, virtually on demand.

“Essentially, we showed that you can rewire a system for a new mission set. [Y]ou can change the frequency and function by simply removing the metal and patterning it in a new place,” Tabor said in a written release. “This can add multiple functions to a single platform, ultimately enhancing mission capabilities.”

The team is in the process of maturing the technology for transition to the warfighter. The biggest challenges include precise control of the interfaces between the liquid metals and traditional electronic systems and the residue left when the liquid metals are removed from one channel and flowed into another, which can cause interference. The researchers also are developing packaging for the material with industry partners to make sure it works in application platforms with traditional electronic systems on board.

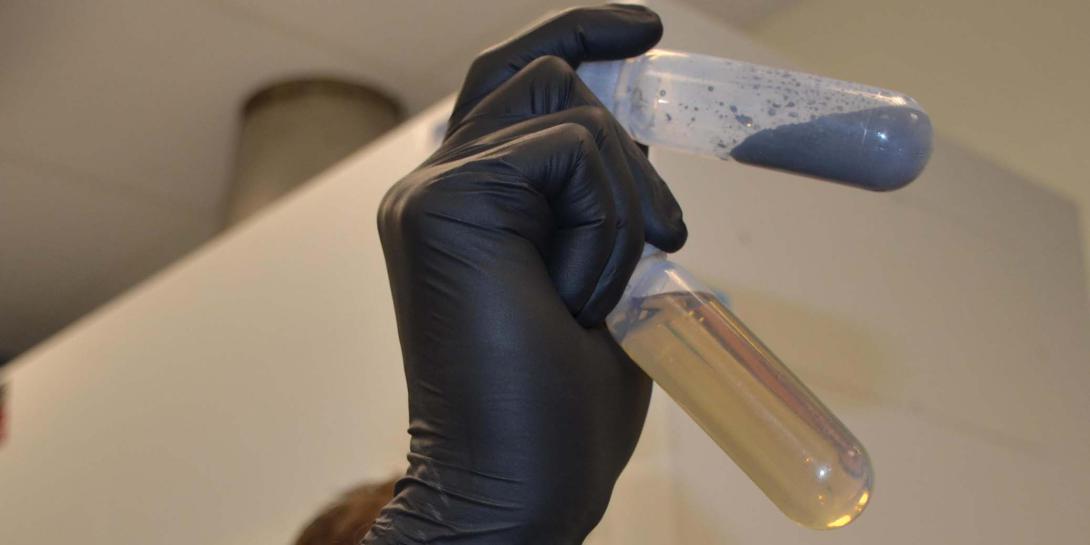

A tandem effort is exploring the potential for liquid metals to power flexible electronic devices, such as human performance-monitoring sensors and wearables. “If you take traditional copper wires and place them on a stretchable material, like a rubber band, the copper wires may break or disconnect,” Tabor said. “Instead, if you make channel systems and fill them with liquid metal, the channels change sizes and the liquids fill them. For electronics that bend and crease, stretch or compress, liquids allow you to maintain stretchability and conductivity.”

AFRL researchers also are looking at a new project to use liquid metals for self-healing electronics. By transforming liquid metals into microscopic nanoparticles, failure points on traditional electronic circuits can be repaired rather than replaced.

The team’s research on liquid metal reconfigurable antennas will be on display during Defense Department Lab Days May 17 at the Pentagon.

Comment

The researchers also are

The researchers also are developing packaging for the material with industry partners to make sure it works in application platforms with traditional electronic systems on board.

Comments