The Sky Is No Limit for NASA Robotics

Robots have led the way for human space exploration, and NASA is counting on them to serve as partners in the next round of endeavors. The space agency is teaming with industry on new technologies that will develop innovative robotic systems and offer capabilities that are key to expanding the reach of humans beyond Earth.

Many of these efforts are part of the agency’s On-Orbit Servicing, Assembly and Manufacturing (OSAM) program. It aims to enable greater capabilities in those three activities, most of which will be necessary for returning to the moon as well as conducting deep-space scientific exploration. New missions enabled by OSAM will support civilian, national security and commercial space, NASA officials say.

“With human space exploration, humans and robotics will be working hand-in-claw,” says Chris Giersch, public-private partnership lead for the Space Technology and Exploration Directorate at NASA Langley Research Center. “If we can relieve mundane day-to-day duties where robots can handle the activities and allow the astronaut to truly explore, that will be a win-win.”

“These capabilities will enable missions that weren’t previously possible,” declares Dale Arney, acting lead for the OSAM National Initiative, NASA Langley Research Center. “The thought of persistent platforms with interchangeable payloads where you’re observing the Earth with multiple instruments at all times, and those instruments are being constantly upgraded, is something that we don’t do right now.”

NASA’s robotics research mostly aims at developing new capabilities. While the agency is pursuing advances in autonomy, that thrust takes second place to developing new ways of exploiting robotics, although some of the proposed new capabilities will require increases in autonomy.

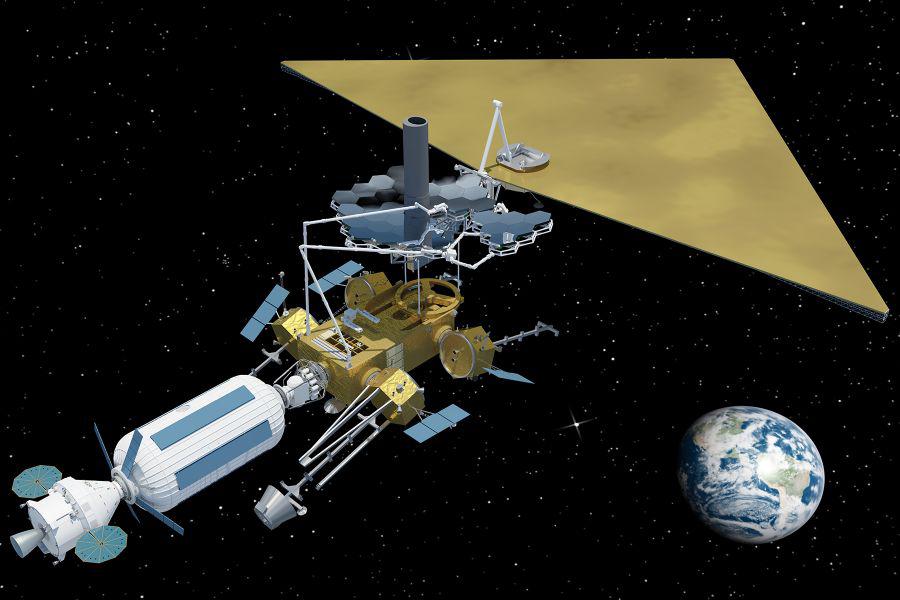

The emerging capabilities to be brought into space by OSAM include inspection, repair, upgrade, modular assembly and construction of space assets, Arney explains, He continues that the OSAM program focuses on its three distinctly different disciplines because each performs a unique function.

For example, servicing addresses on-orbit alteration of a spacecraft after it is launched. This encompasses repairing faulty or failed equipment, upgrading or improving hardware and refueling to increase satellite lifetime. Assembly involves bringing together multiple components in orbit to build a vehicle that could not be launched whole because of weight or volume. And manufacturing entails the on-orbit or lunar surface transformation of raw material into spacecraft components, as is done with 3D printing onboard the International Space Station. Arney explains that the moon would provide some of the raw materials that would be used for construction there. In earth orbit, where raw materials for construction are lacking, some materials will be launched in a separate vehicle for manufacturing.

All three of these disciplines rely on robotics to an increasing degree, and as missions grow more complex and ambitious, the sophistication of robotic technologies must increase accordingly. NASA is applying new approaches to technologies that also will depend to a greater degree on autonomy.

“When an environment is understood, and you define the scope, then autonomy can be implemented quite well and quickly,” Arney offers. “It’s those environments where everything is uncertain and you’re not really sure what you’re going to get. That’s where all the hard work goes into making it happen.

“Going forward, if we’re going to assemble really large telescopes or surface infrastructure on the Moon—things that are large, fairly complex and cost-competitive using different methods—we’re going to have to go toward more automated operations, so you don’t have a whole team of people on the ground screwing every bolt in,” he says.

While the focus currently is on satellite servicing, robotics advances open the door to building bigger satellites and more persistent spacecraft with refueling and upgrade capabilities, Arney says. These advances should enable many new capabilities and create businesses that may not be on the radar right now.

“A large observatory in space that can image exoplanets or see their composition is groundbreaking,” he continues. “On the human exploration side, sustainable exploration is a buzzword for what we do after the 2024 Moon landing. The set of capabilities in OSAM is really the foundation of sustainable exploration.”

The first element of the OSAM effort is the OSAM-1 mission. Formerly known as Restore-L, the mission now comprises the Space Infrastructure Dexterous Robot, or SPIDER, and MakerSat, which is a Tethers Unlimited payload. Slated to be launched in 2023, OSAM-1 will test telerobotic servicing for spacecraft not designed to accommodate this capability. The spacecraft’s mission profile calls for it to autonomously rendezvous and capture the Landsat-7 satellite, which it then will refuel telerobotically. SPIDER will demonstrate robotic assembly of a communications antenna for communications tests with ground stations.

MakerSat will demonstrate microgravity manufacturing of a lightweight carbon composite beam, Arney continues. He explains that each task has its own set of robotic arms. One set is for capturing the target spacecraft autonomously and telerobotically for refueling, and it has a quick-disconnect tool switchout system mounted on its end. There is room for more tools if planners decide to add to mission tasks, he says. A smaller set, being developed by Maxar, will build the antenna.

These devices largely employ telerobotics, in which a human operator guides the device remotely. But systems far away from Earth cannot rely on that, so NASA is pushing to increase the autonomy in its robots. “Autonomy is a huge focus right now of the technologies we are working on currently,” Arney says. Even near-Earth applications will require autonomy. “If we want to assemble something affordably and quickly, we can’t have the human in the loop like we’ve had in the past. We have to be able to allow the assembly agent to operate on its own to assemble these vehicles.”

On Earth, researchers at Langley are working on autonomy along with modeling and simulation, Arney reports. The goal is to take the human out of the loop and allow the robotics to operate on their own with only human supervision.

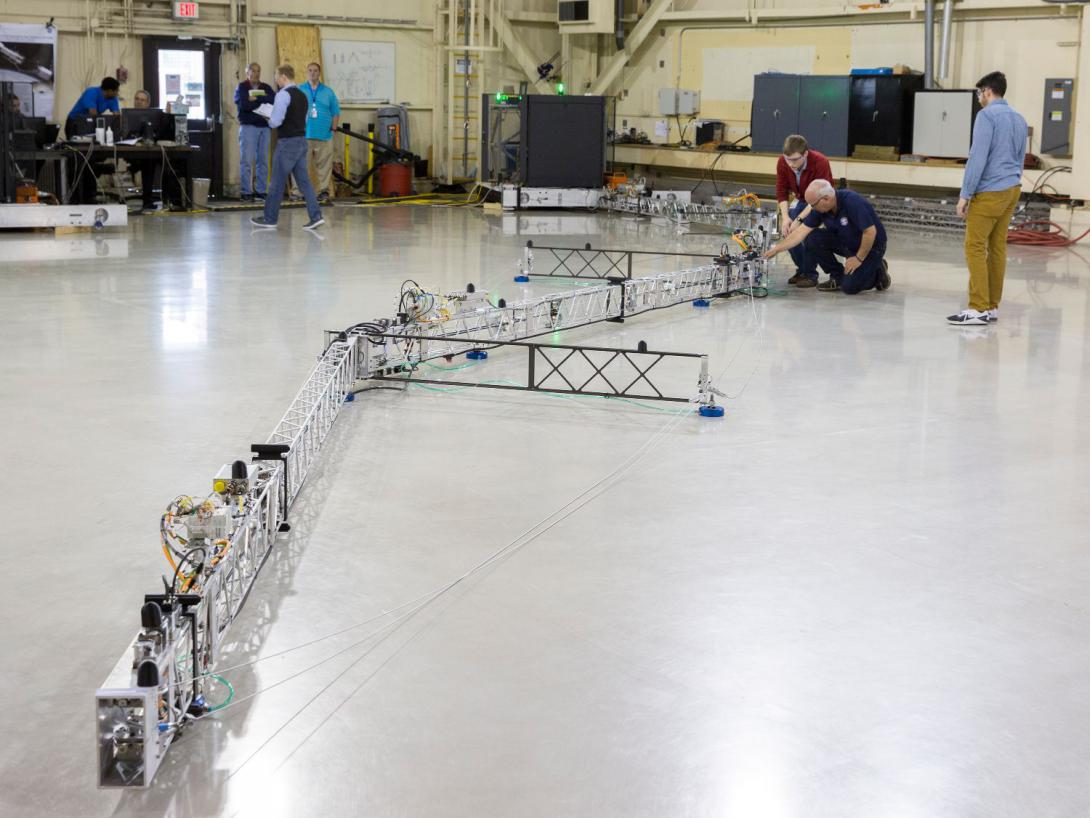

These researchers also are developing a robot arm known as Tension Activated Lightweight In-Space MANipulator, or TALISMAN. True to its full name, it uses artificial tendons as long as 20 meters to move the arm. This device packs smaller and lighter than comparable arms, Arney notes. A surface version of TALISMAN, the Lightweight Surface Manipulator System (LSMS), is designed for payload offloading, potentially on the lunar surface, Arney says. “It’s almost a robot arm all to its own, but it’s very scalable,” he adds.

After OSAM-1 comes OSAM-2, formerly known as Archinaut One. This will constitute a vehicle built by Made In Space Inc., that will use additive manufacturing to build a 10-meter boom for a solar array. Arney states that this boom will pull out solar arrays that would be able to produce 10 times the power as traditional folded solar panels.

Future missions will differ depending on whether they focus on civil, commercial or military space applications, Arney allows. Civil space robotics will pursue advances that reflect on five main thrusts: human exploration, astrophysics, heliophysics, planetary science and earth science. “That means large telescopes, persistent assets on orbit and infrastructure on the lunar surface or around the Moon to support human exploration.” Lunar facilities will require shielding from radiation and dust, which calls for buried structures powered by solar or nuclear structures, he notes.

One of the challenges inherent in enabling robotics in a vehicle is that the capabilities must be built into the system from the start. Arney explains that engineers cannot simply attach robotic capabilities to a bus. Instead, they must be designed into the vehicle to operate optimally.

Then comes verification and validation. These functions can be performed easily on Earth, but a space-based construction poses a host of problems in these areas. Researchers are still working on how to perform verification and validation on systems assembled in space, Arney maintains.

Even rendezvous and proximity operations, which are not new disciplines, will require more advances as new robotic capabilities are pursued. Some cases will require long-reach manipulation, Arney points out, which is where experiments such as the TALISMAN system can come into play.

Above all, the processes for robotic manufacturing and assembly need refining. These could range from basic space welding to connecting diverse assembled parts and their supporting functions.

As with all autonomous vehicles, artificial intelligence (AI) will be an increasingly important aspect. Arney explains that NASA has a group at Langley working on autonomous operations, and they are drawing on AI advances already developed for unmanned aerial vehicles. Future NASA AI likely will draw on advances in other aerospace sectors.

NASA also hopes to benefit from the Defense Advanced Research Projects Agency’s (DARPA’s) Robotic Servicing of Geosynchronous Satellites (RSGS) effort. While this would have a servicing capability similar to OSAM-1, its vehicles would go far beyond low earth orbit to the geosynchronous altitude of 22,236 miles above the surface. This vehicle will be commercially owned and operated coming out of a public-private partnership with Northrop Grumman’s Space Logistics LLC, where the company owns the vehicle and all the operations.

On the commercial front, Northrop Grumman is working on the Mission Extension Vehicle, or MEV, which docked with an Intelsat satellite in February. This represented the first time a vehicle autonomously captured a satellite in geosynchronous orbit, Arney reports. The MEV bus will serve as the basis for the RSGS.

The commercial sector is playing a large role in space robotics, Arney reports. Satellite servicing already has transitioned from government-funded to commercial-driven needs, with the MEV as a prime example. RSGS, while funded up front by DARPA, will be a commercially operated vehicle. Other companies with programmatic visions of space exploitation are pursuing robotics functions, he adds.

“I think everything that we have accomplished so far has been a partnership,” Arney states.

Giersch notes that NASA works with established space firms as well as with new space companies around the country on robotics technologies. Entry, descent and landing are hot topics for many of the companies. Large antennas are on the radar for commercial robotic construction capabilities. For proposed lunar missions, including commercial ventures, off-loading technologies are important for future lunar exploration and exploitation.

“We’re seeing multiple companies that have reached out to us to ask about off-load capabilities,” he adds.

“When we get to the lunar surface, construction is going to be vital to ensure that our astronauts are working in a safe environment and our technologies are going to be protected,” Giersch points out. This will require shelter and landing pads for supply ships, which will need to be constructed using robotic technology.

Comments