Structure, Heal Thyself

|

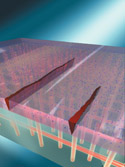

| A structural beam with surface cracks has been healed through supply of healing agent from the underlying vascular bed. In testing at the University of Illinois, surface cracks were repeatedly healed up to six consecutive times with no loss in healing efficiency. |

Developers are laying the scientific groundwork for a totally new concept in materials engineering. If successful, the results could have major implications for commercial and government products through the creation of immortal materials.

Scientists at the

“Our initial target is to create a self-healing structural material that repeatedly heals multiple times,” explains Dr. Byung-Lip Lee, program manager for Mechanics of Multifunctional Materials and Microsystems, AFOSR. If perfected, the microvascular healing could lead to materials that continue to heal and recover indefinitely, even at the same location. The developers working on the material have demonstrated its ability to heal a specific spot six times. The repeatability is important because if material defects are present, the material can continue to fail at the same location.

The materials heal by releasing a liquid phase healing agent from the vascular bed into the surrounding polymer matrix material. The microvascular system has two versions. In one version, a solid-phase catalyst is included in the matrix, and the healing chemistry is initiated by contact of the catalyst and the liquid healing agent upon fracture. In the other version, two liquid phase healing agents mix in the fracture plane—after being released from two separate vascular networks—and the healing reaction initiates upon mixing.

The system also has different versions for its self-cooling capabilities. In one version, a coolant is circulated throughout the vascular network by pumping (active) or convective (passive) transport. In another version, the healing agent provides the healing functionality, transports heat through the network and cools the surrounding matrix. “Self-cooling is important for providing thermal protection to polymer-based composites, for maintaining precise thermal control for sensitive instrumentation and for expanding the application range for polymer composites,” Lee says.

For the full potential of systems to be realized, the vascular network must be three-dimensional because all engineering structures are three-dimensional. The transport of the healing agent from locations far removed from the point of damage requires the use of a three-dimensional interconnected network.

The types of materials being studied in the experiments are commercial systems currently used in a broad cross-section of industries including aerospace and microelectronics. The multiple capabilities of the microvascular materials have various applications. The thermal control could be immediately applied in microelectronics and the computer industry. The structural applications of microvascular materials could be applied in areas such as robotics (via stiffness control of self-healing) or unmanned aerial vehicles for increased robustness and reliability.

Despite the range of uses for the materials, Lee shares that the materials will not be immediately available for widespread use. “Perhaps eventually such a concept would be pervasive, but initial applications will be specific,” he explains.

The idea for creating microvascular materials was introduced by Professor Scott White of the Beckman Institute at the

The microvascular materials are being tested through several different experiments by a full team of 11 personnel. The scientists look at the mechanical behavior of microvascular material using new and proven experimental techniques. New methods are being developed based on digital image correlation, which allows the researchers to map the stress and strain fields on a surface of a material on a very precise scale. They also look at how healing takes place in the systems and measure how much structural recovery the systems are able to achieve as time passes. “In a nutshell, we break them, let them heal, and then break them again,” White explains. The researchers also use experimental techniques called micro particle image velocimetry to view how fluid moves through the circulatory systems in the materials.

Another application for microvascular materials is in self-cooling or thermal management in which coolant circulates through the systems. The scientists use infrared technology to track fluid temperatures with laser-induced fluorescents.

The concept behind White’s original work was to encapsulate reactive phases and then place them into the materials systems. His team looked to nature for inspiration because natural life deals with a limited supply of resources and depends on a circulatory network to replenish itself. The researchers’ ideas progressed from a compartmentalized approach to a system with a circulatory network, which could heal indefinitely, essentially making a material that is immortal. “That was our initial motivation behind trying to build materials with microvascular networks,” White shares.

|

| Up to 100-layer-tall microvascular networks have been made by the direct-write assembly of an organic ink followed by infiltration with an epoxy matrix. |

However, the potential for multiple applications is evident. The Air Force is interested in the products that have immediate uses within the military, including structure applications and microelectronics in which polymer composites are used as well as coatings on airplanes and ships. White says the microvascular structures can be used ubiquitously where polymers and poly composites are used now. In terms of additional functionality such as thermo stasis, the materials can be applied in various areas where protecting a critical component from environmental exposure or high temperatures is necessary. In those cases, the self-cooling feature—and not the self-healing one—would play the primary role.

White and his team are building a microvascular material by working with commercially available polymers and reinforcements. “We’re not developing new polymers or new chemistries, per se,” he explains. “We’re using ones that are available to us.”

To fabricate the systems onto the material, the developers use direct-write assembly, which involves a robot. The robot is programmed to write with ink in a specific pattern on one material layer. It repeatedly advances upward in space and writes on top of the last layer. What the robot writes is the vascular network in three dimensions. The scientists then infiltrate the network with a polymer such as epoxy and solidify the polymer. The result is an epoxy matrix with ink in the form of a vascular network. Ink has a thermal transition, so it will melt and then is vacuumed out, leaving channels inside the epoxy. “That’s one example of how we build these kinds of microvascular materials,” White states. The types of materials the team infiltrates are used widely in many industries.

Despite the progress the team has made with the microvascular systems, the public should not expect to see the materials on the shelf of the local hardware store soon. “This is very new stuff and very cutting edge,” White says. “It’s going to be a while before it’s fully developed and matured.” For years, scientists have discussed biomedical approaches and bio-inspired design for material creation, but that process historically has been limited to synthesizing new materials that exactly mimic visible structures. “Our approach here is not to mimic nature but to be inspired by it,” White explains. The team looks at the natural systems as a whole and then questions how to replicate the functions in synthetic materials. Materials constructed currently are static and degrade with time, but with the implementation of circulatory systems, the materials could heal and maintain temperature throughout a structural lifetime, thus eliminating wear and tear.

Lee shares that while the healing and cooling features could work in a dual network, such a format has complications, and at this point, the two properties will be handled separately. The microvascular network for self-healing typically will reside in a sensitive region susceptible to damage. Cooling usually happens near the surface, so a self-cooling network should be placed there.

By 2010, the Air Force hopes to have a laboratory-scale, aerospace-type-grade composite containing microvascular self-healing and self-cooling features. At the least, the service would like to have a prototype of a fiber-reinforced composite with the two microvascular capabilities. According to Lee, many of the materials used in a Boeing 787 are made of composite materials that are very strong but tend to exhibit tiny cracks. He says those cracks pose little problem for overall construction, but make the material unsuitable for fuel storage tanks because the fuel leaks. To cure the problem, the Air Force needs a way for the material to heal itself. Lee compares the microvascular material and its applications to the human body. For a major problem, such as a broken bone, people need a doctor, but for small scratches the skin heals itself. In the same way, a major structural problem would need attention and repair, but a small crack in material could repair itself on its own.

The Air Force initially sponsored research on self-healing polymers and polymer composites in which a capsule opened, resin spun out and reacted with a catalyst and healed the material on the spot. The drawback to the method was the one-shot deal with no way of replenishing if another problem occurred at the same location. To resolve the issue, the

After a year of work, the scientists realized they could use the system for the self-cooling function as well by circulating a coolant in a local area. One possible future use for that feature is to cool the leading edge of airplane wings flying at high speeds. While the idea has yet to be tested, Lee says in time the Air Force may try using the microvascular materials as a wing tip.

Web Resources

Air Force Office of Scientific Research: www.afosr.af.mil

Beckman Institute: www.beckman.uiuc.edu

Microvascular Autonomic Composites: www.mvac.uiuc.edu

Comments