U.S. Maritime Services Implementing Acquisition Innovation

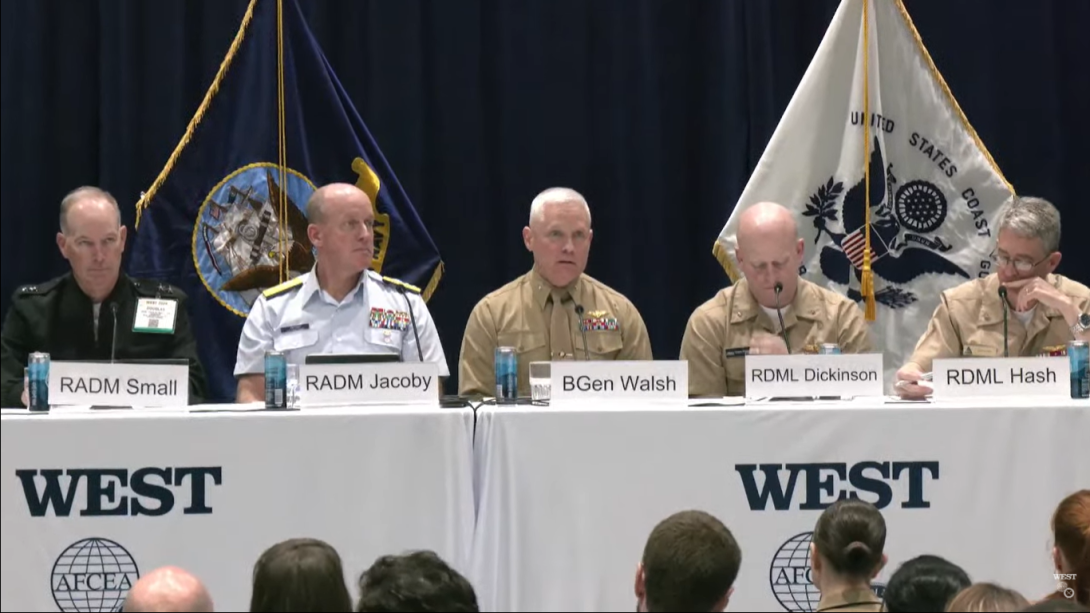

A panel of admirals from the U.S. Navy, Marine Corps and Coast Guard reported that their respective organizations are implementing an array of improvements to acquisition and contracting processes for more rapid delivery of new technologies to warfighters.

The panel reported progress during the second day of the February 13-15 WEST 2024 conference in San Diego.

Rear Adm. Douglas Small, commander, Naval Information Warfare Systems Command (NAVWAR), echoed comments that Adm. Samuel Paparo made during a keynote presentation earlier in the day that the Navy “will never ever be satisfied that we can go fast enough,” but he asserted that there are areas where the service is moving pretty quickly. He cited a few examples, including the SpaceX Starlink network of satellites.

“When I first got here, there was no p-LEO [proliferated low-Earth orbit] constellation that you could put antennas on every single ship before they deploy, and now we put three of them on aircraft carriers and one on every other ship that’s deployed,” Adm. Small reported, offering that the Navy has pulled industry along in terms of providing what the service needs for warfighting information.

He also described NAVWAR as a “fully fledged software factory delivery machine” that has delivered “hundreds of applications over the air to ships at sea” and trained “hundreds of sailors” on how to use them. “That is just the way we now do business,” he added.

Furthermore, he said, the Navy’s Project Overmatch, which is the Navy’s contribution to the military’s vision for joint all-domain command and control, is “running with scissors” to develop and field capabilities as rapidly as possible.

Brig. Gen. David C. Walsh, commander, Marine Corps Systems Command, said that along with the Capabilities Development Directorate, his organization has established a “transition team, a fusion cell, that will help pull initiatives, to pull technologies” from low technology readiness levels in the science and technology world to “transition them quickly to a program of record.” He explained that the Marine Corps acquisition community is tied closely with the science and technology community early to set up budgets and smoothly transition technologies. Furthermore, the Marines are “going for effectiveness over efficiencies” in contracting rather than trying to “squeeze every dime out of a contract.”

Rear Adm. Thomas Dickinson, commander, Naval Surface Warfare Center (NAVSEA) and the Naval Undersea Warfare Center, also highlighted the need to experiment and transition technologies quickly and cited Task Force 59 as an example of innovation. “We’ve had over 60,000 hours at sea, 34 different operations, events and exercises over 23 different platforms there in theater.” Those events include “the Fourth Fleet hybrid campaign event where we evaluated unmanned systems and advanced kill chains down in [Southern Command] and countless number out in the Pacific in the same vein,” Adm. Dickinson noted.

In a few months, across the warfare centers and across the NAVAIR community, we solved that problem, and it was double the amount of critical weapons they needed on those platforms.

Rear Adm. Keith Hash, commander, Naval Air Warfare Center, Weapons Division, and assistant commander for test and evaluation, Naval Air Systems Command (NAVAIR), said that his organization has done assessments on some of the acquisition challenges and their root causes. They found that 70% of capabilities are being delivered late but that the organization intends to overcome challenges and is focused on delivering capability, availability and affordability. He indicated the Navy has saved $1 billion that can be reinvested in game-changing capabilities.

As an example, he offered the Navy’s Joint Simulation Environment, a government-owned training facility that helped evaluate the initial operational capability of the F-35 in complex threat environments. “We’re now going beyond F-35 and integrating the rest of the Navy and now Air Force platforms, both air and surface weapons, to make sure we can use that quality environment for the future, current programs and future programs.”

Naval Air Systems Command also met a joint operational need for forces serving in the Red Sea to protect shipping lanes from Houthi rebels. Navy forces in the area needed to increase the weapon capacity of F-18 Hornets. “In a few months, across the warfare centers and across the NAVAIR community, we solved that problem, and it was double the amount of critical weapons they needed on those platforms.”

The problem was solved, he added, by sitting down with engineers and analyzing the data and possible solutions rather than taking the time to conduct more flight tests.

Adm. Hash also reported that he is personally leading some pilot projects that are reducing the acquisition timeline by months “for weapons and for platforms, delivering software on an iterative basis.” That, he added, builds a margin so that when acquisition challenges arise, capability deliveries are not delayed.

Adm. Dickinson said NAVSEA has used additive manufacturing to certify more than 500 parts. “We have a policy in place now where it’s authorized to additively manufacture low-criticality parts, so as long as we have a requirement met in terms of form, fit and function, the fleet has the green light to produce those parts. Across our platforms, we’ve had over 4,000 parts produced via additive manufacturing,” he said. “We’ve got a long way to go there.”

Comments