Army Makes a Point of Putting Lasers on Vehicles

The U.S. Army is moving closer to putting high-energy laser weapons on individual vehicles to improve its short-range air defense capabilities. The weapons meet the Army’s need for counter-rocket, artillery and mortar fire and protection for unmanned aerial vehicles and unmanned aircraft systems—the latter of which is particularly important, given their abundance. Laser systems offer substantially lower cost per fire than traditional weapons, and their stealth firing characteristics make them valuable countermeasures for intelligence, surveillance and reconnaissance operations.

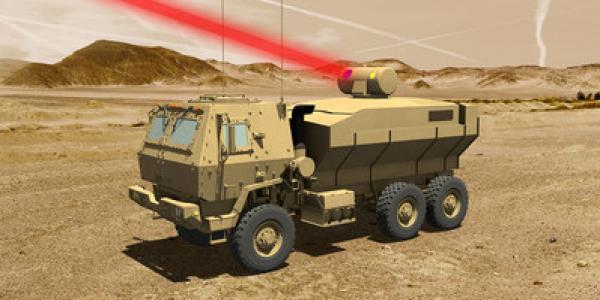

As with everything a mobile Army uses, size, weight and power issues are crucial considerations. The entire laser weapon system—laser, beam controller, power, thermal management and other systems—has to fit on an Army vehicle such as the Stryker or the Heavy Expanded Mobility Tactical Truck (HEMTT). The weapon also must be able to operate successfully in the rugged environments the Army faces.

The High Energy Laser Division of the Army Space and Missile Defense Command/Army Forces Strategic Command (SMDC/ARSTRAT) is charged with advancing laser technologies to meet the requirements of Indirect Fire Protection Capability Increment 2–Intercept (IFPC Increment 2-I), ground-based weapon systems designed to defeat cruise missiles and unmanned aircraft systems (UAS). The division has several robust programs to tackle the challenge, including the High Energy Laser Tactical Vehicle Demonstrator (HEL TVD), the High Energy Laser Mobile Test Truck (HELMTT), the Robust Electric Laser Initiative (RELI) and the Mobile High Energy Laser (MEHEL).

So far, the work has been going well, says Adam Aberle, the division’s high-energy laser technology development and demonstration lead. “From the standpoint of doing our high-energy laser scientific and technology development—maturing the technology and demonstrating that the laser does have an effect on targets that are of interest to the Army—we have been very successful,” he says.

The SMDC is pursuing two paths for evolving high-energy laser technologies to support their transition into programs of record. The first path, the HEL TVD, involves the development of a 100-kilowatt-class laser weapon to tackle IFPC Increment 2-I capabilities for fixed and semi-fixed applications. Army officials envision the weapon fitting on the Family of Medium Tactical Vehicles (FMTVs). A vehicle’s sole purpose would be to carry and engage the laser system, which would provide short-range air defense (SHORAD). The SMDC plans to build the HEL TVD system in fiscal year 2021, then demonstrate and gather data in the next fiscal year, with the ultimate goal of transitioning a 100-kW-class HEL TVD into that program of record, Aberle confirms.

The second path for maturing high-energy laser technologies aims to put a 50-kW multimission system on a Stryker for mobile applications needed for the Army’s maneuver brigades. The SMDC is looking to help inform the Army on refinements for the weapon for future use in maneuverable SHORAD. As of mid-October, the SMDC was still conducting source selection for both the 50-kW and 100-kW systems, Aberle says.

Another program, MEHEL, began in late 2015 when the SMDC formed a cooperative agreement with General Dynamics Land Systems (GDLS) and Boeing, with GDLS as the lead integrator for placing Boeing’s 2-kW Compact Laser Weapons System (CLWS) on a Stryker.

“At very significant operational ranges, you can blind an enemy drone while preventing the enemy from seeing your location,” says Jim Leary, director, Boeing weapons global sales and marketing. “It’s a very significant capability, especially when you think about the way that the Army operates in sort of autonomous operating bases. You have to protect the operating base from both direct attacks and observations.”

Leary noted that Boeing’s system employs a commercial off-the-shelf laser. “It’s the same laser that car companies use to cut hoods at the plant,” he says. “With an off-the-shelf laser, you can interchange your laser power with the beam director, and that’s what makes it so attractive to the customer. It’s scalable.”

Boeing reports signing an undisclosed production contract last year. Company officials envision protecting the forward edge of the battlefield by putting the CLWS on various platforms—including the Apache helicopter. “We tried to get the CLWS as small as possible while keeping lethality,” Leary says.

After initial success at last year’s Maneuver Fires Integration Experiment (MFIX) at Fort Sill, Oklahoma, the CLWS returned to MFIX in April as a 5-kW 2.0 version, with enhanced power and electronic warfare capabilities. In the soldier-run exercises, warfighters operated the laser, received commands and neutralized a number of threats within certain Army formations, explains Kendall Linson, GDLS business development manager. “This type of experience is crucial because the laser is very fast, very lethal and very unforgiving,” he says.

Because the Army fights differently than the Air Force or Navy—with brigade combat teams—soldiers have to sustain themselves independently on the battlefield, and they need both kinetic and nonkinetic options, Linson points out. “The Army’s approach to this is that there is no single capability that we can integrate on the battlefield today. It’s going to be a multiple layer, tiering effect, integrating the laser in with other weapons such as the Maneuver SHORAD Launcher,” a universal weapons interface, he imparts.

At the next MFIX this month, MEHEL will continue to inform the development of laser weapon tactics, techniques and procedures, Aberle offers. To that, Linson adds, “We are going to integrate a 10-kW laser on that same vehicle and test it, adding a target acquisition radar.” The system will track its own targets without having to be on a network. This allows operators more flexibility not only to get a network feed of targets but also to find a slew of their own targets, he says.

During the Joint Improvised-Threat Defeat Organization’s (JIDO’s) UAS Hard-Kill Challenge earlier this year at White Sands Missile Range, New Mexico, MEHEL was used to go after single and multiple targets. It adroitly handled target acquisition, pursuit, aim-point selection and defeat of smaller UAVs, claims John Matlock, Boeing program manager for networked air defense. “We’ve had very good success in engaging 80 different targets,” Matlock says.

The laser, which is invisible, has a very short shot duration. Boeing found that it took just seconds to engage, fire and hit a target. Leary adds, “The CLWS has shot down drones of various sizes as far out as a couple kilometers and as close in as a couple hundred meters.”

More importantly, the JIDO challenge helped soldiers change their firing techniques. They learned where and how to use the laser to take down different targets, either going for the UAV motors or electronics. With some UAVs, such as inexpensive Styrofoam models, the laser is more like a blowtorch that blasts a hole right through the foam but does not necessarily bring down the UAV on the first shot, Matlock recounts.

Turning to the RELI program, the SMDC and Radiance Technologies are integrating into HELMTT a 60-kW-class beam combined fiber laser system created by Lockheed Martin—with a goal of working up to a 100-kW-class laser. The SMDC is removing HELMTT’s 10-kW system and replacing it with the 58-kW system Lockheed Martin delivered in June to the command’s Technical Center in Huntsville, Alabama. According to Lockheed Martin, the combined fiber laser is the most powerful one ever demonstrated.

To create it, Lockheed Martin took fiber lasers and combined them into a single high-power beam to reach up to 60 kW of power, says Rob Afzal, senior fellow for laser and sensor systems at the company. The key is beam quality—a measure of how well the beam keeps focused as it projects—along with high electrical and optical efficiency, he imparts. “For the high-power laser to be effective, you need to keep it concentrated on the target. Our ability to show that we can take a large number of fiber lasers and combine them and maintain beam quality is what is enabling our technology to become useful for Army applications,” Afzal says.

Army applications are demanding. A truck has limited space and ability to carry weight, so a laser system “has to be compact, very efficient [and] rugged enough to be driven down a bumpy road,” Afzal says. Furthermore, the laser weapon must be efficient, be able to defend against abundant threats and be able to operate for long periods of time. “It’s not just one target every now and then,” he observes. “Along with ruggedization, the deep magazine was an important design component for the Army.” Another consideration was for the optical system to have a 360-degree view to engage in threats from any direction. Lockheed Martin also is looking at hardening the system from defensive cyber and electronic warfare standpoints.

As for managing the heat in a vehicle-based laser, Lockheed Martin looked for simple coolants already in the Army’s inventory. “As sophisticated as the high-power laser technology is from an optical perspective, we’ve also tried to make the support systems [relatively simple],” Afzal says.

The company’s Accelerated Laser Demonstration Initiative (ALADIN) fiber laser employs a coolant made of water and propylene glycol—essentially a food-grade version of antifreeze. “This is something that is not exotic,” Afzal says. “It avoids adding unnecessary complexity to the soldier who has to maintain these laser systems.”

Initially, the SMDC’s integration of the Lockheed Martin laser into HELMTT resulted in an associated loss of power, Aberle said, but scientists have restored it to 60 kW. “To increase the output of the laser, it really depends on the architecture of how the laser is built,” he says. “The technology in the RELI system uses a lot of parallel fiber laser amplifiers aimed together. And while there are naturally limits to that architecture, you can easily get it to a 100-kW-class laser.”

Going forward, the SMDC will use the RELI system “to anchor models and collect data to verify performance of the 50-kW-class laser as a total system,” including activities next August or September at White Sands, Aberle shares.

Comments