Researchers Have Artificial Skin in Robotics Game

A research team at the University of Texas at Arlington may one day cover robots and prosthetic devices with nanotechnology skin to provide them with a sense of touch far superior to humans.

A sense of touch could allow for greater precision and control. A robot needs to know, for example, how much pressure to apply when picking up an elderly patient from a bed, an airplane engine from a factory floor, or a glass of champagne from a tabletop.

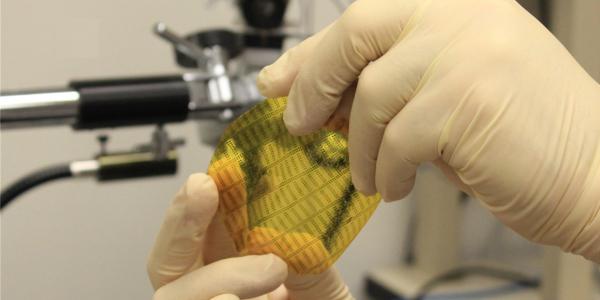

The smart skin, recently patented by the university, is actually made up of millions of flexible nanowire sensors that take in much more information than human skin. The sensors are made of zinc oxide nanorods that do not need any external voltage for operation. Each is about 0.2 microns in diameter, while a human hair is about 40 to 50 microns, according to a published announcement.

To the naked eye, the material looks like a thin membrane, but at the microscopic level, it appears a little hairy. Some on the research team refer to it as “hairy robot” technology because the nanorods give it a carpetlike appearance.

The nanorod array and the electrodes are embedded in layers of flexible polyimide, which provides mechanical support as well as moisture and dust resistance. Polyimides are known for being strong and chemical- and heat-resistant. They can be used in circuit boards, microwave ovens, fuel cells and computer displays. “The middle layer, even if you bend it or roll it, is at a no-stress plane. You have a top plane and a bottom plane and a middle plane, sandwiched between a substrate and a superstrate,” explains Zeynep Çelik-Butler, a University of Texas at Arlington electrical engineering professor who leads the research. “If you were to bend it or curve it, the curved section is under compression and the top is under tension, so somewhere between the compression and the tension, there’s a plane where the device doesn’t feel any stress at all.”

The smart skin material could be used for a number of applications, but prosthetics and robotics are two top possibilities. Because lower-body prosthetics are primarily designed for stability, Çelik-Butler envisions the material being used more for arms and hands. “High sensitivity is important for whatever is going to replace your hands. Whenever you pick up your glass, you don’t break your glass, but you don’t drop it on the floor either. You know exactly how much pressure to apply,” she says. “Your brain, of course, knows that, but you don’t need your brain for that. You can have algorithms that can do that.”

Smart prosthetics is a growing area of research. The Defense Advanced Research Projects Agency (DARPA) has supported prosthetics research, and so has the U.S. Army. Çelik-Butler suggests, however, that much of the current technology provides either “very good-looking hands and arms” that “don’t do anything” or “clawlike functioning hands” that provide no sensory feedback. Additionally, current prosthetics often require some kind of movement of the shoulders or other body parts to make them function. “There is a lot of work going on in this [area], but there is really no skin that would allow you to do just simple things—pick up a glass or coffee cup without very carefully moving your shoulders or whatever the prosthetic is connected to,” she states.

In robotics, touchy-feely machines may make better partners for humans. “It is frequently desired that a robot, especially one that is involved in human interaction, acquires tactile information from a large area on its surface for safe and effective operation within its environment,” Çelik-Butler writes, along with two co-authors in an IEEE Sensors Journal research paper. “As a result, any sensory network on the robot surface should ideally cover a large area, conform to various topographical features on the robot and provide tactile information to the robot with minimal energy consumption from the robot’s limited power resources.”

The university team has completed laboratory testing, putting the smart skin at a technology readiness level of about six on a scale of zero to 10. Çelik-Butler notes with a laugh that the readiness level is considered “the valley of death” for research because it is a challenge to transition technology from the lab to the commercial world.

“We don’t do field testing at all because we’re a nonprofit organization. Once we do the research, we put the news out and wait for companies to come to us—and they are coming,” she reports. Her team has loaned samples to three companies for field testing. Çelik-Butler says she is not ready to name the companies or to report what stage of testing each one is currently conducting.

Assuming all goes well, the smart skin could be put to use pretty soon after the field testing. “The device is ready to be used, but the device by itself cannot be used. It has to be part of a system, in the subsystem, and it needs to be integrated into whatever goes onto the prosthetics or whatever goes onto the robot,” she says.

The ultrasensitive artificial skin also may be used to identify fingerprints. “You don’t need to press it. You would not need any ink. You would not need any of that. It could even look like paper to someone who is holding it. Our devices have a very low profile, so the person might not even know that you’re measuring their fingerprints,” Çelik-Butler asserts.

Asked whether the material could be used for facial recognition as well, she laughs again. “I don’t think someone wants to ram their face into a nanorod array,” the professor quips.

The material generates an electric charge when pressure is applied, which is known as a piezoelectric effect. That means it also might be used for harvesting small amounts of energy. “The bending, the tactile pressure, actually powers it. Think of a carpet being shaken. When you do that, it vibrates. It’s going to generate voltage,” Çelik-Butler explains. “It could be on an airplane or anything.” She adds that she has worked with a defense contractor to integrate the smart sensor technology onto an airplane but can’t provide details.

In theory, the smart skin also may replace wires in small devices. “You can have distributed sensors all over your smart skin, and if they are self-powered or if they can power other sensors next to [the material], then you don’t have to run those wires,” Çelik-Butler says.

Robots also may present opportunities for energy harvesting. “Let’s say you have a robot arm doing the same thing over and over and over again. When it moves, it vibrates. It moves at a particular frequency. It accelerates and decelerates. And it produces work in the physics sense,” she offers. “That motion is not very much, so I need to be able to harvest the energy used up in this motion. I need something very small that will move with it—like a hair.”

For energy harvesting, the material is at about a technology readiness level of four, Çelik-Butler estimates. The team is now tweaking the zinc oxide with other materials to increase the piezoelectric properties.

The smart skin has its roots in military technology research the professor conducted in the 1990s with infrared sensors. “The only thing that is common between the early sensors and what we are doing is the substrate and the superstrate. What you put in the middle, the sensor itself, is different,” she reports.

The smart skin technology can be easily manufactured at relatively low temperatures—300 degrees Celsius, or 572 Fahrenheit, or less. Semiconductors are typically manufactured at much higher temperatures, but in this case, the conformal plastics would melt.

In other words, the technology, relatively speaking, is literally cool.

Comments