Army Plans Swat Teams Of Mechanical Bugs

|

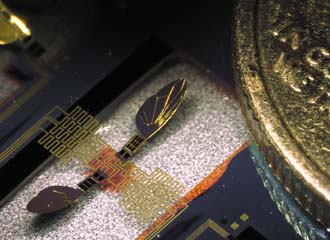

| A pair of wings less than 5 millimeters across are designed to power a sensor-bearing robot that would fly in the same manner as a common mosquito or fruit fly. The wings are made of piezo-electric material that serves to control their motion. The larger curved object to the right is a Roosevelt dime. |

When the U.S. Army needs to determine if an area on the battlefield is safe or is threatened by hidden menaces, it may be calling on its own custom-made mosquito air force to probe the area and report back to headquarters. Army researchers are developing life-size robotic sensor platforms based on small flying insects.

These manmade flies would follow the design architecture perfected over millions of years of evolution by well-known bugs. Army Research Laboratory scientists are using piezo-electric materials as the basis for fully mechanical flying insects. These bio-mimetic devices not only would resemble common winged insects, they also would fly using the same motions employed by their organic counterparts.

The advantage offered by mimicking insect flight is that insects are able to perform maneuvers beyond the capabilities of modern conventional robotic aircraft. Insects’ wing motion allows them to fly at slow speeds and to hover in confined spaces, yet they can accelerate rapidly.

While other efforts have developed wing-driven aerial robots, these micro air vehicles have tended to be hand-sized and unable to hover or maneuver as well as small flies. The new Army research is looking at developing flybots as small as fruit flies that can perform aerodynamically just like their natural cousins.

Ronald G. Polcawich, team lead for the laboratory’s millimeter-scale robotics program, explains that the program began two years ago as a director’s research initiative to examine the feasibility of creating microflying sensors at the millimeter scale. These would serve as cueing sensors for larger platforms for both situational and tactical awareness.

Polcawich’s team is using piezo-electric actuation to propel small-scale robots at the millimeter scale. These millimeter-scale robots would operate both on the ground and in the air. The ground-crawling versions might resemble scorpions, while the airborne versions would mimic insect motions such as stroke as well as pitch and frequency amplitudes. The airborne mechanical devices would carry sensors that communicate their findings back to either a battlefield information network or other larger and more complex sensor platforms.

The main program thrust has been to generate motion and mobility with these small-scale structures, Polcawich reports. Piezo-electric actuators take advantage of materials with electrical properties. Just as these types of materials will produce electricity when they are flexed—the direct piezo-electric effect—their motions can be impelled and controlled when small voltage currents are applied to them.

Polcawich explains that the laboratory’s piezo-electric actuators comprise a lead zirconate titanate (PZT) thin-film that, when voltage is applied to it, creates strain. This strain is translated into vertical motion. He emphasizes that the laboratory is striving within aeromechanical design constraints to create actuators for stroke amplitude—the vertical flap—along with angle-of-attack pitch.

The two years of research has allowed Polcawich’s team to develop structures that provide both stroke and pitch motions. The scientists have been able to achieve “numbers that are within the biological realm,” he reports. These work out to stroke amplitudes of 85 degrees and pitch amplitudes of about 35 degrees, which are similar to those of insect performance.

These actuation movements have been achieved using less than 20 volts of power, he adds. Power supply is a challenge for any device the size of a common housefly, and the laboratory has been focusing on low-power solutions that will provide the characteristic performance necessary for flight.

One possible source would be solar panels. These might be placed on the mechanical fly’s body and wings. The wings themselves might be made of solar panel material, Polcawich suggests. Another potential source is energy harvesting. Polcawich allows that the energy harvesting community is evaluating vibrational energy harvesting, which would tap electricity from other piezo-electric devices that would shed power when subjected to vibration. This power would be stored for use by the flybot.

To develop these advanced microsystems, the laboratory is exploiting micro-electromechanical system (MEMS) approaches. Polcawich says that the piezo-electric actuator technologies currently developed by the laboratory team are based on MEMS fabrication technology. The devices are built on silicon wafers using a repeatable and robust process.

|

A close-up of a 1.5-millimeter flybot wing shows the lattice structure that allows it to flex in flight. Note the three thin-film piezo-electric actuators at the base of the wing that enable multidirectional motion. |

The individual wing platforms that the laboratory has built have wings ranging from 1 millimeter to 3 millimeters long. So, a two-wing platform built from these constructs might have a wingspan ranging from 2.5 millimeters to 6 millimeters. The largest flybot would have a wingspan shorter than a quarter of an inch.

“With systems of this scale, we look at it from a situational awareness and stealth attribute,” Polcawich explains. “When you shrink things down further and further, the stealth characteristic becomes very high.”

Because these systems are so small, their functionality must be “targeted and limited,” Polcawich notes. “Although you would love to have ultrahigh-sensitive sensors, these platforms potentially would limit the ultimate sensitivity.”

Their most likely application would be in swarms used to cue larger assets with higher-fidelity sensor platforms. For example, one robot fly might have a temperature sensor programmed to cue in the presence of a specific temperature range. When it detected that temperature, it would notify a larger, more elaborate sensor, which then would investigate in finer detail.

In another application, a robot fly might be designed to detect a large presence of a biological or chemical compound. Again, the small device would notify a larger platform bearing a better sensor that could focus on the same area and parse its own data for more specific situational awareness.

Polcawich suggests that a future deployment might feature a packbot releasing a swarm of these smaller sensors to seek out their sensor targets under doors, over walls or in other somewhat inaccessible areas. Then, it would cue the packbot or the network as to a positive detection. That cue might either spawn greater investigation or warn personnel to proceed more carefully.

Over the next couple of years, the program will transition from a director’s research initiative into three directorates focusing on mission performance. Scientists will aim to demonstrate lift and sustained microflight, Polcawich says. Then, it will be linked with the Army’s Micro Autonomous Systems and Technology (MAST) effort, which currently is examining handheld and smaller robotic platforms.

Even though the laboratory is building bio-mimetic devices, Polcawich explains that it currently does not have anyone on its team who has a biology background. The laboratory has leveraged “the wealth of literature” on insect architecture and entomology. Through collaborations with the MAST effort, the laboratory is able to tap some biological expertise. As the effort proceeds, it may bring in bio-mimetic experts to fine tune its engineering.

“Everyone on the team feels confident that we’ve demonstrated the feasibility [of the technology],” he says. “We’re hitting the biological milestones that put it in the realm of insects, and we feel confident that we have that.”

The toughest hurdle has been proving the technology’s feasibility, Polcawich states. The prime focus has been on demonstrating independent control of stroke and pitch for the device’s wings. Sustaining microflight will be a future hurdle, as scientists will need to ensure that the integrated control and power system can sustain airborne operations. Researchers also must develop drive waveforms and control algorithms to optimize wing lift.

Polcawich does allow that the team will be tapping outside expertise for the flybot’s power supply. The laboratory will leverage outside partnerships to develop power technologies small enough to support the microrobot. Developing a power supply system that can incorporate necessary power conditioning circuits in a millimeter-scale footprint—and sustain the flybot for the duration of the mission—is a challenge that will require outside assistance.

“As long as we can try to keep the voltages and drive currents low enough—and the power requirements low enough—then hopefully we and outside partners can develop the power systems for this.” These systems must both generate lift and power the sensor payload, he adds.

Some sensor technologies to equip the flybots may come from the MAST program, Polcawich offers. Most of the current MAST sensors are hand-sized, so their work would need to focus on smaller technologies.

The only operative sensor that applies to the millimeter-scale devices is a piezo-electric sensor that is placed in the wing. This sensor, an offshoot of the device’s piezo-electric material, is used only for feedback control for flying the device. The two orthogonal piezo-electric sensors provide information on the wings’ stroke and pitch.

Comments