New Technique Allows Faster 3-D Printing

By using laser-generated, hologram-like 3D images flashed into photosensitive resin, researchers at Lawrence Livermore National Lab (LLNL), along with collaborators at UC Berkeley, the University of Rochester and the Massachusetts Institute of Technology (MIT), have discovered they can build complex 3-D parts in a fraction of the time of traditional layer-by-layer printing, according to an LLNL press release.

The novel approach is called “volumetric” 3-D printing, and is described in the journal Science Advances, published online on December 8.

“The fact that you can do fully 3-D parts all in one step really does overcome an important problem in additive manufacturing,” said LLNL researcher Maxim Shusteff, the paper’s lead author. “We’re trying to print a 3-D shape all at the same time. The real aim of this paper was to ask, 'Can we make arbitrary 3-D shapes all at once, instead of putting the parts together gradually layer by layer?' It turns out we can.”

The approach overlaps three laser beams that define an object’s geometry from three different directions, creating a 3-D image suspended in the vat of resin. The laser light, which is at a higher intensity where the beams intersect, is kept on for about 10 seconds, enough time to cure the part. The excess resin is drained out of the vat, and researchers are left with a fully formed 3-D part.

The approach, the scientists concluded, results in parts built many times faster than other polymer-based methods, and most—if not all—commercial additive manufacturing methods. Due to its low cost, flexibility, speed and geometric versatility, the researchers expect the framework to open a major new direction of research in rapid 3-D printing.

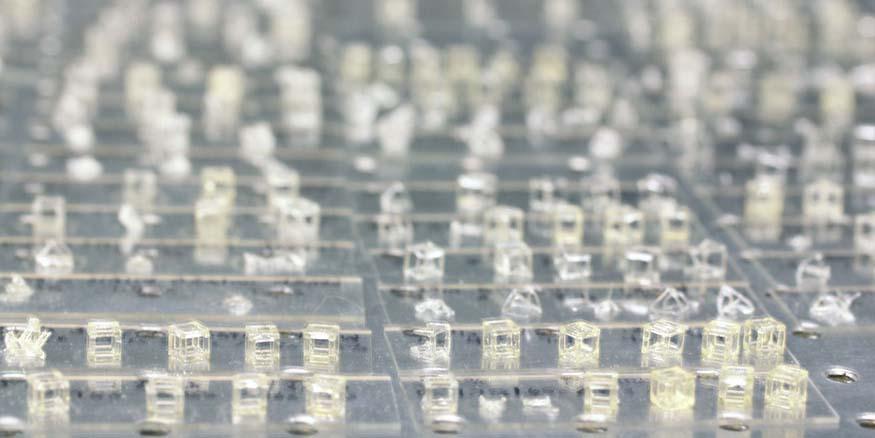

With this process, the researchers printed beams, planes, struts at arbitrary angles, lattices and complex and uniquely curved objects. While conventional 3-D printing has difficulty with spanning structures that might sag without support, Shusteff said, volumetric printing has no such constraints; many curved surfaces can be produced without layering artifacts.

Volumetric printing could be made even faster with a higher power light source. Extra-soft materials such as hydrogels could be wholly fabricated, he said; otherwise they would be damaged or destroyed by fluid motion. Volumetric 3-D printing also is the only additive manufacturing technique that works better in zero gravity, expanding the possibility of space-based production.

The technique does have limitations, researchers said. Because each beam propagates through space without changing, there are restrictions on part resolution and on the kinds of geometries that can be formed. Extremely complex structures would require lots of intersecting laser beams and would limit the process, they explained.

Furthermore, additional polymer chemistry and engineering also would be needed to improve the resin properties and fine tune them to make better structures.

Comments