Practicality Drives 3D-Printing Trends

Additive manufacturing, also described as 3D printing, is opening up new pathways to production. While many of these are dead ends as economics and logistics limit some of the hoped-for applications, others offer the potential to be game changers in the manufacturing arena.

Printed body parts are taking shape in laboratories, but printed industrial parts may not always fit the bill. Issues such as reliability, integrity and longevity must be determined on a case-by-case basis as custom parts are devised and built.

Yet the limitations demonstrated by custom manufacturing also could be the rationale for additive manufacturing to dominate a niche industry. The economies of scale, which can hinder the reopening of an assembly line to build a small number of replacement parts, do not apply to additive manufacturing and may be a supporting rationale for its application.

The need to custom design parts for an individual use is leading to more applications of the technology. Replacements for some human body parts already are being built using additive manufacturing, and the process offers even greater potential in this arena.

Vicki A. Barbur, senior director of technology and integrated processor commercialization at Battelle, views additive manufacturing as “a technology that can address every possible problem and solution that we need.” However, its solutions do not always suit the problem. “For niche applications, it certainly has demonstrated its value, but not necessarily for the broader landscape,” she states.

It does provide flexibility and a great capacity to deal with complexity, she continues. But it doesn’t really provide a solution for many straightforward applications such as building a square-edged cube, for example. This use would be relatively costly and time-consuming compared to conventional manufacturing techniques.

Another issue confronting additive manufacturing is the number of technological unknowns that can plague a part, such as integrity or longevity. Additive manufacturing comprises several different processes, and their standards and testing regimes remain to be identified and put in place, Barbur points out. These standards and tests must be incorporated to determine part reliability, especially under harsh conditions or where human life is at stake. Regulatory bodies are still working on how to validate additive manufacturing parts, she adds.

Additive manufacturing works when an object has complex characteristics that the process can address directly. In some cases, the process has allowed engineers to exceed the performance levels of conventional manufactured parts. Many of these conventional parts are made by subtracting material, but 3D printing builds parts by adding material, Barbur notes.

Additive manufacturing also increases the ability to create modular parts, she continues. Individual parts can be built in small segments that can be validated before assembly into a larger unit.

The military is benefiting from additive manufacturing by replacing parts in legacy systems that no longer are made, Barbur points out. Starting up an entire assembly line for spare parts would be prohibitively expensive and time consuming, whereas additive manufacturing can build custom parts faster and at much less cost.

Engineers also are at work designing large additive manufacturing machines that might move into major parts construction, she continues. One new use would employ concrete in additive manufacturing, which could revolutionize the construction industry for buildings and bridges. Many steps necessary for today’s construction methods could be eliminated by the efficiencies of the new process, she says, adding that this industry could be the next one disrupted by additive manufacturing.

Traditional assembly lines that use large machines could, in some cases, be replaced by smaller additive manufacturing devices. These units would be safer than large pieces of moving equipment occupying a factory floor, for example. It also would remove the repetitiveness of traditional manufacturing, Barbur offers. “It means that manufacturing becomes more high-tech.”

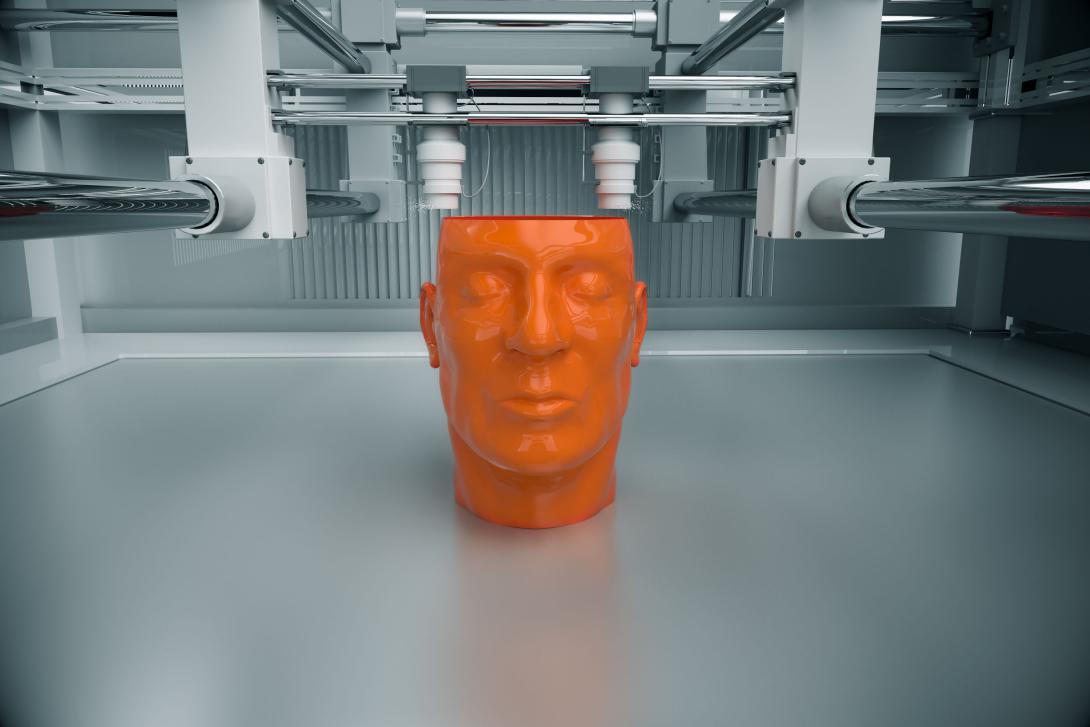

Body parts can be a major market for additive manufacturing. Artificial joints, for example, can be customized to fit individual people as needed, instead of pulling devices off the shelf and adjusting them—or their human recipients. With today’s technology, a body area can be scanned to provide relatively precise measurements for building a part to fit. Medical uses that require a great deal of personalization and customization can be well-served by additive manufacturing, she suggests.

The medical arena is rife for growth in additive manufacturing, she explains. Body parts tend to be small and need to be customized, and the utility of additive manufacturing comes into play with items that are needed only on an ad hoc basis.

Many additive manufacturing technologies are similar to inkjet technologies, Barbur notes. They lend themselves to construction of human organs, which would go beyond construction of skeletal parts.

A human kidney, for example, is rife with tubes. “This technology is ideal for being able to create those structures and, again, to customize them to the person that needs them,” she states. “It may be that you’re not making a whole kidney; it just might be the diseased part of the kidney—or a diseased part of a heart,” she suggests.

Shortages in transplant organs could be alleviated if actual replacement parts could be manufactured synthetically. Sensory organs such as eyes and ears could benefit as well. “There is so much that could happen if we could create these parts and create them as they are needed,” she posits.

“Biomaterials is the area that is going to be revolutionary,” Barbur argues. “You could put these organs together, and the mind boggles as to what you could create.”

Whatever the application, fast prototyping is a key component in the viability of additive manufacturing. Engineers use this approach to examine new designs and test new structures quickly. After that process, the customer—the government or a commercial manufacturer—picks up where the prototyping left off to move toward full-scale manufacturing.

Barbur relates that her firm employs rapid prototyping for parts in which it is trying to improve performance specifications. “If you can redesign the part and test it, you have that ability with additive manufacturing,” she allows. “So we don’t have to go outside to get it refabricated—we can do it internally.”

As the process has progressed, new technological hurdles have popped up on the path to future applications. The biggest challenge lies in trade-offs: some of the faster additive manufacturing technologies offer parts with lower integrity than a system that moves slower, Barbur offers. Metal parts, for example, must last longer than those built of polymers.

One issue is how to join additive manufacturing to other materials. The joint could be a site for corrosion or an unwanted chemical reaction, depending on the joined materials. Barbur says that joining issues must be understood better before designers could be sure that their additive manufacturing components work as well as desired.

Composites will be used to a greater degree as applications broaden. They will bring many different features, Barbur says, but they will encounter the joining barriers. “Thinking about that ahead of time is going to help us be prepared,” she adds.

Artificial intelligence and machine learning can help generate additive manufacturing designs for specific applications, she continues. Bringing together all these digital changes will be the ultimate determinant for success.

Regulatory issues also pose a challenge. If additive manufacturing is to be used to build complex body parts such as hearts and kidneys, manufacturers will have to please the U.S. Food and Drug Administration (FDA). Ultimately, the FDA must be willing to accept this approach to organ replacement, Barbur allows. “It will not be easy to replace a kidney without being able to validate that this approach doesn’t endanger the patient,” she says.

And other types of regulation may loom. The technology has spread to the home front, with some people having their own 3D printers in their households. This provides a good introduction to the process, Barbur offers, in that people can create harmless and convenient items such as personalized smart phone covers that will not cause a harsh consumer reaction if they break the next day—the owner will just print another.

However, manufacturing a component at home that could have life-threatening applications would be cause for concern, she adds. “Like the Internet, these things have to be discussed and considered ahead of time—like stem cell research and other issues where we put in rules and regulations afterwards.”

Comment

Interesting piece on

Interesting piece on additives manufacturing and open source infrastructure. I'll see if I can track down the companion piece about what the US Gov't are doing around 3D manufacturing out of their Oak Ridge facility. Which, by the way, is only a couple of hours away from Tullahoma.

You will get clear details

You will get clear details from the article given over here, it states about practically drives for 3d printing trends.I really loved it and thank you very much for sharing this with us. You have a great visualization and you have really presented this content in a really good manner.for more info:-https:// www. fuson-cncmachining. com/

Comments