Startup Companies Push Aerospace Innovation

Innovative pioneers looking to bring their ideas and concepts to reality are pushing the edge of aerospace capabilities. In some cases, the technologies are the result of university research, while others come from markets outside of defense. The entrepreneurs purport that their technologies will be, if not groundbreaking, useful and more efficient. The entrepreneurs presented their nascent products and discoveries at a pitch meeting hosted by The MITRE Corporation in McLean, Virginia on October 11 as part of Starburst Aerospace Accelerator’s annual East Coast Selection Committee event.

Headquartered in Paris, Starburst's U.S. team brought in 10 hopeful companies all vying for partnership agreements, venture capitalist funding and a chance to join Starburt's Accelerator Program. The event pairs the startups with potentially interested corporations, investors and government agencies. The companies’ prospective products, which range in level of technical readiness, cut across all aspects of aerospace, from power generation to rocket engines, satellite-enabled encryption and unmanned aerial vehicles.

MITRE’s Barry Costa, director, Partnerships and Technology Transfer, emphasized the importance of partnerships in harnessing innovation across the industry and government to bring the best skills and technologies in support of the nation and a safer world. “MITRE believes we are stronger together,” Costa said. A not-for-profit organization, MITRE operates seven federally funded research and development centers (FFRDCs) across the government. In its active role of “innovation bridging,” MITRE is working to find “the best that the commercial market has to offer,” so that it can bring those technologies to bear on U.S. government challenges. In addition, MITRE licenses select intellectual property (IP) to private industry to help spur the economy and bring federally funded IP to market as supported products, Costa said.

In its third year helping to guide aerospace startups, Starburst has expedited 234 startups, with 42 percent of those companies receiving their first significant round of venture capital investment, known as series A funding, through the effort, said Van Espahbodi, Starburst co-founder and managing partner. Espahbodi shared that more and more startups participating in the Starburst Aerospace Accelerator program “come from places we haven’t imagined.” The company offers early-stage entrepreneurial support, as well as later-stage acceleration programs. As part of that effort, Starburst coordinates events around the world. In December, Starburst is hosting a West Coast Selection Committee in the Bay area.

Last year’s East Coast Accelerator event, held at DARPA, brought in improved battery efficiencies, 3D metal printed antennas, software for manufacturing improvements and drone delivery applications, among other cutting-edge technologies. Three of the companies from that 2017 event—Optisys, Fore Dynamics, and Ampaire—were selected in September to be part of Starburst’s late-stage acceleration program, according to Espahbodi.

The 10 companies featured in the 2018 East Coast Selection event at MITRE included:

Los Angeles-based Centauri is developing a next-generation rocket engine, according to Brandon Pearce, co-founder and CEO. The engine, meant for small to medium payload (<4000 kilograms) launch vehicles, employs a new propulsion technology. “Centauri Space Systems’ new engine technology could improve engine specific impulse by 34 percent or more, which will triple the deliverable payload to space,” Pearce contended.

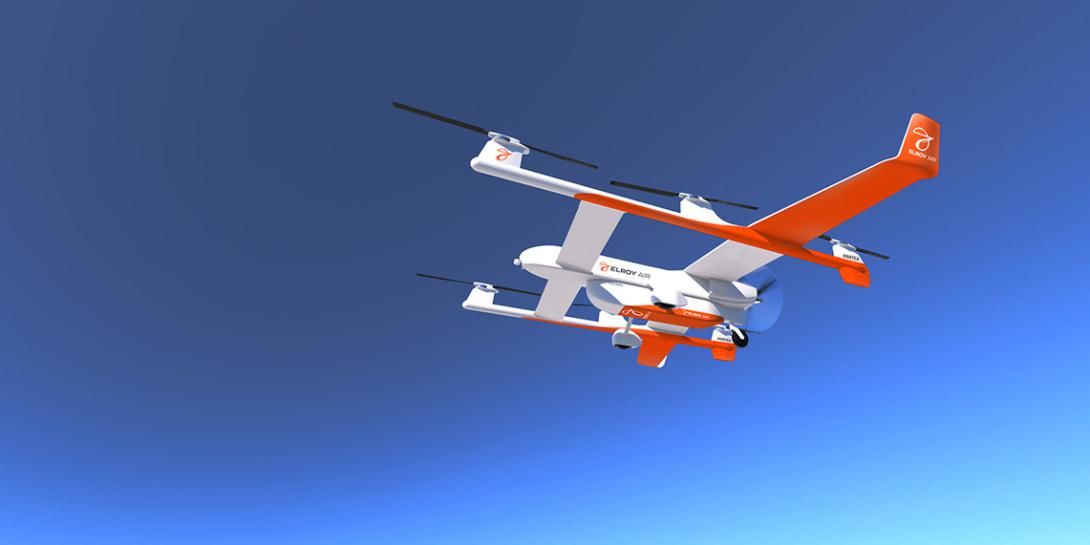

The autonomous aerial cargo aircraft systems from San Francisco-based Elroy Air will be an alternative to ground transportation for those last 100 miles in remote locations, said David Merrill, co-founder and CEO. The aircraft system with a hybrid powertrain takes off vertically with an electric rotor-based vertical takeoff and landing (VTOL) feature and transitions to a fixed wing mode for forward flight that uses an internal combustion engine for efficiency and long-range cruising.

The robotic aerial cargo system picks up preloaded cargo pods, carrying 200-500 pounds of payload by air over a range of 300 miles. When ready to land, it scans the landing zone to ensure clear space before landing and depositing the cargo. The autonomous system enables point-to-point deliveries without the need of an airport, Merrill said.

The company envisions the systems’ use for package deliveries in remote locations, immediate relief in disaster scenarios and rapid autonomous resupply for military troops in the field. “This aircraft will be the Ford F-150 of the sky,” Merrill said. The company is taking a phased business approach, first seeking government customers that already control their own airspace. Once the Federal Aviation Administration (FAA) policies regarding large unmanned systems are established, the company will support commercial applications. Elroy Air plans to complete its initial phase of full-scale testing in the first quarter of 2019 and trial flights with customers later that year, with a goal of flying commercially in the United States in 2022.

A 2014 spin-off of the University of Pennsylvania’s GRASP Laboratory, Exyn Technologies is offering drones that can operate autonomously in confined, “obstacle-rich” spaces, said Nader Elm, CEO. The Philadelphia-based company’s advanced autonomous aerial robot, known as A3R, uses multiple redundant sensors and artificial intelligence to enable real-time, on-board mapping for obstacle avoidance and autonomous flight planning. Meaning, “it runs without user intervention and does not require a map or GPS,” Elm said. The robot “sees” the environment and dynamically generates its optimized flying path. Its fully automated data acquisition can be used for inspection and surveying surveillance and mapping reconnaissance, Elm explained. The company’s initial development is currently focused on single unit unmanned aerial vehicle (UAV), and then it will move to developing UAV swarms.

Philadelphia-based Ghost Robotics is building a next-generation military robot. The Q-UGV or quadruped unmanned ground vehicle is fast, agile, maneuverable and unstoppable at a fraction of the price of other legged robotic systems, CEO Jiren Parikh claimed. As a legged robot, it works better on unstructured terrain—such as stairs, rocky ground and soft surfaces—and can be trained to manipulate the environment. It outperforms robots with wheels and tracks, Parikh contended. “We’ve created the first size-scalable design, that is easy to use and can be programmed and integrated with third-party sensors and software platforms for security, situational awareness and soldier surrogate applications,” he said.

Ghost Robotics’ software stack, including its control platform that builds various robot behaviors, is highly modular and accessible through an application program interface. With the open architecture, stakeholders can develop their own applications and integrate their own electronics, including sensors and radios onto the platform. The company is already generating revenue and has received other transaction agreements from various DOD programs, including DARPA. Formal industrial and military pilots will begin in early 2019, Parikh noted.

Warren, Ohio-based Petra Power is developing auxiliary power systems for defense and the commercial aircraft industry, using solid oxide fuel cell power units, CEO Aaron Goodman said. The solid oxide fuel cell offers a 90 percent increase in fuel efficiency compared to traditional combustion engines, as it operates at higher specific power and power density. The fuel cell systems are highly modular and can support power needs from 1 kilowatt (kW) up to 500 kW, Goodman noted. The rugged systems are simple to manufacture and have an extended operational lifetime, he noted. The power unit can be used in air, land and sea applications and runs on a variety of commonly available hydrocarbons, such as jet propellant 8 (JP-8), diesel or gasoline, with no need to reform or desulfurize the input fuels, Goodman said.

Boston-based Poly6 is working to solve limitations of turbo machinery components, said Keith Hearon, co-founder and CEO, Poly6. The company streamlines traditional process engineering to enable customers to manufacture products with previously unachievable designs in a variety of materials, including ceramics, elastomers and metals, according to Poly6. To support the design of more efficient jet engines and lower the cost of component materials by as much as 30 percent, Poly6 offers polymeric-based consumables, software and associated hardware and additive manufacturing (3D printing) to improve the manufacturing of turbo machinery, Hearon noted.

Currently in the industry, there is a backlog of engine orders. In addition, turbo machinery performance is limited by design constraints, as the more challenging components are harder to manufacture, Hearon explained. Poly6 offers process and system efficiencies to solve these challenges, and uses several “stimuli-responsive” materials systems in the integration of hardware and software for the production process. The company emerged from Langer Lab at Massachusetts Institute of Technology in 2016, Hearon said.

Founded in 2017, Ventura, California-based PteroDynamics is developing a transwing VTOL aircraft, according to Matthew Graczyk, CEO. The VTOL is a 100 percent rotorcraft when it needs to be and converts to a fixed wing, Graczyk explained. “It transitions from a pure multicopter configuration, for taking off and landing, into a pure fixed wing configuration for forward flight,” he said. The airframe design, which is optimized for distance, can be scaled to be small or very large. And it can use electric or wet fuels. The company envisions that the aircraft will enable new industries, from drone delivery to air taxis, Graczyk said.

Toronto-based QEYnet is offering a secure global satellite system for protected communications, explained Cordell Grant, CEO. The startup, founded in 2016, is developing satellite-based quantum key distribution (QKD) for encryption. QKD, which uses a stream of polarized photons to create secret encryption keys, is the most secure cryptography available, but it is limited by the loss of information across optic fibers. QEYnet solves the problem of long distance (<100km) relays by creating “trusted nodes” via satellites, allowing multiple users to be securely connected regardless of distance, Grant stated. QEYnet constellation can scale with demand, and only requires a single satellite to begin serving customers.

Santa Monica, California-based RED6 Aerospace is developing an augmented reality (AR) ecosystem for use in military aircraft, boats and cars. One product, called Atari (Advanced Tactical Augmented Reality Integration), is a flight system that can supply a joint augmented battlespace that can more adequately prepare fighter pilots in advanced air combat maneuvering than a ground simulator system, said Daniel Robinson, the company’s founder and CEO. Robinson, a former F-22 pilot in the U.K. Royal Air Force, explained that traditional AR employs camera optical tracking, which does not work well outdoors or in dynamic environments. Operating in high fidelity to track planes at high speeds, Atari provides a solution to this problem. It allows fighter pilots to train against any adversary, real or imagined, in a realistic way. And while existing live, virtual and constructive training can simulate environments to train pilots, it does have limitations. “You can’t see live airplanes,” Robinson said. Atari puts “live virtual” into the windscreen of a jet. The platform can help reduce the expense of training pilots, which can cost the military an estimated $400 million a year, Robinson said.

Founded in 2013, Los Angeles-based Rufus Labs produces wearable technology tools and accompanying software that create a link between humans, the Internet of Things and robots, according to Gabe Grifoni, CEO and co-founder. The company offers products known as the Rufus Cuff and the Rufus Scan, which enable data collection and streamlined communication to improve logistics or manufacturing workflow. The Rufus Cuff is a 4.3-inch wearable, ruggedized touchscreen that has 15 hours of battery life. It runs the complete Android operating system and allows for text, voice and video messaging. “The Rufus Cuff provides hands-free communication tools and includes sensors that allow for physiometric data collection, location-based assignments, alerts and safety checks,” Grifoni noted. All data gathered by Rufus Labs' devices can be accessed through a dashboard platform.

Comments