Scientists Pick AI for Lab Partner

The U.S. Air Force’s most prolific scientist likely will never wear a lab coat, but it can perform experiments 100 times faster than its human counterparts. The robo-researcher may one day help spark explosive growth in scientific knowledge.

The Air Force Research Laboratory’s (AFRL’s) Autonomous Research System (ARES) does not fit the conventional idea of a robotic system. It is not humanoid. It does not move freely across the ground or fly through the air. But in a single day, it can autonomously execute 100 experiments, compared with about one for its human peers.

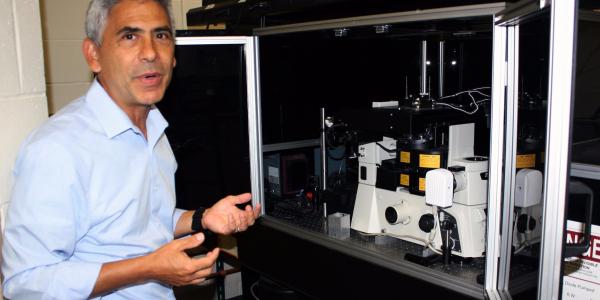

“The ARES ... is programmed using the same kind of software programming approach that’s used for autonomous robotics,” says Benji Maruyama, senior materials research engineer, Functional Materials Division, AFRL. “It doesn’t have arms and legs. It doesn’t roll around. But it takes action based on an analysis of the data that’s there. It operates a microscope; it operates a laser; it operates gas flow controllers.”

The ARES, which belongs to the AFRL’s Materials and Manufacturing Directorate, experiments with revolutionary materials, including graphene and carbon fibers and nanotubes. The system’s benefits go beyond speed. The ARES analyzes data from previous experiments and uses that information to determine the next best experiment.

“Every time we do an experiment, we are able to update our understanding so that artificial intelligence has a new piece of information that makes the selection of the next experiment even better,” Maruyama offers.

He relates the story of a visiting professor from Vanderbilt University who used the ARES to accomplish “a dissertation’s worth of experiments” in three days. “Normally, it takes three years of lab work to get your dissertation,” Maruyama adds.

The ARES appears to be one of just three robotic systems in the world conducting scientific research and the only one exploring advanced materials. The other two, Adam and Eve, were developed by a team at Aberystwyth and Cambridge universities. Adam is credited with being the first machine to independently discover new scientific knowledge in 2009.

Maruyama theorizes that artificially intelligent machines could rapidly accelerate the growth of scientific learning. He compares the potential growth to Moore’s law, which states that computer processing power will double approximately every two years. “Projecting out 20 or 30 years, there could be essentially an explosion in scientific understanding if we, as a community, adopt research robots on a wide scale. What if we were able to have a Moore’s law for the speed of research?” he inquires. “It’s blue sky. We’re not claiming that at this point, but it’s out there as a goal for us.”

In the laboratory, as on the battlefield, human researchers will remain in the loop, making decisions and taking actions that cannot be left to machinery, Maruyama maintains. “The robot’s not there to replace a human researcher but to augment and to team and partner with the human researcher,” he says. “Defining the research problem, digesting results and translating that artificial intelligence and machine learning into fundamental scientific understanding is the job of the human researcher.”

Maruyama indicates that he takes some heat from colleagues worried that robots will one day take their jobs. “I think not. I think it’s more like a computer,” he counters, adding that no one complains when a computer becomes more efficient. He also points out that artificial intelligence (AI) can do the work not only faster but also more cost-effectively. “It’s a good thing. We can attack harder problems,” Maruyama states.

In fact, he suggests that AI systems will attract more humans to science and engineering. For one thing, a sudden burst of scientific knowledge will require more people to use that knowledge and find practical applications for it, Maruyama allows.

Furthermore, robots do not mind doing the dirty work. “Students who want to get into science and engineering ... come into the lab ... and they pay their dues. They wash test tubes, and they do tedious kinds of lab work,” he explains. “If the robot is taking on that tedious work, humans get to jump in and do the things humans are good at: that creative, insightful work, which is why we get into research in the first place.”

Essentially, AI lowers the barrier to entry for people interested in science and engineering. “If we spread a lot of these research robots around, we could all be doing a lot more research a lot faster, and we would all make better progress,” Maruyama observes.

In the coming weeks, the AFRL team is exploring the possibility of having the ARES perform other kinds of research. “We’re franchising the ARES method. We’re applying the ARES to other research problems,” Maruyama reveals. “We’re looking, for example, at using it for 3-D printing. A 3-D printer is already a robot. If we can use the closed loop, iterative ARES method, then we can learn how to print new inks and new structures much faster than we do now.”

The team intends to license the software and the ARES method to others, a possibility that still is in the concept stage but could be ironed out in a few months. Using the traditional method, a researcher comes up with a hypothesis and then sits down to design a campaign of experiments, possibly 10 or 20. Once the experiments are done, the researcher analyzes the results to determine whether the hypothesis was correct.

He describes traditional research as still being humancentric and rooted in the Dark Ages, despite myriad high-tech tools such as lasers and electron microscopes. “There’s not enough automation in the lab. Researchers go around with timers on their lab coats just so they have a reminder to turn the burners off at the right time,” Maruyama states. “We have today autonomous robotics, artificial intelligence machine learning and computational power. My intent with the ARES is to bring all that to bear on the research process itself.”

Comments