Meet Laser-Triggered, Origami-Like Pixie Dust

U.S. Army researchers have developed micro materials that fold when hit with a low-intensity laser. The advance may eliminate the need for relatively bulky power systems—such as battery packs—on tiny robotic systems. It also could enable robotic microthrusters, unattended ground sensors, or even—theoretically—programmable, easily changeable camouflage patterns.

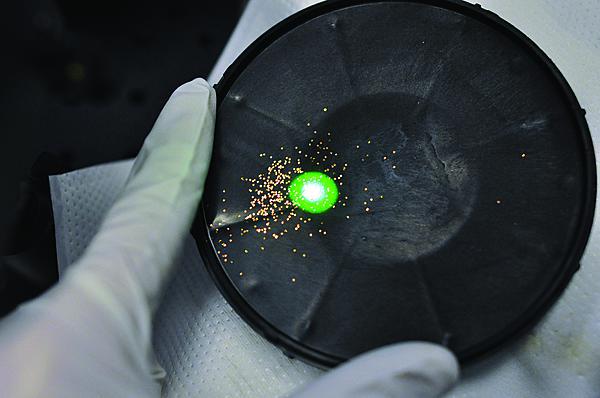

The microelectromechanical systems (MEMS) are shaped like stars with four, six or eight legs. The legs fold—like origami—when heated slightly with light from a low-level laser. That folding action is accomplished without the materials being tethered to batteries, wires or other any other power supply.

One of the most likely applications would be a new kind of switch that prevents electricity leakage when a device is turned off. “You could turn on a structure or turn off a structure from a distance by shining a light on it,” explains Chris Morris, an Army Research Laboratory (ARL) electronics engineer who leads the On-chip Energetics and MEMS team. “And when the structure is in an off state, it would be truly off, unlike a solid-state electrical switch where there’s always some leaking through even when it’s off.”

Microrobotic applications are more futuristic. “I could see this as potentially being a way to enable very, very small robotic-like platforms where you have little legs that would move in response to light—and potentially even different colors of light, so they could be directed to walk in one direction or another depending on what color of light you’re flashing at them,” Morris explains. “That’s one interesting aspect that circumvents the current power supply challenge with small-scale robotic systems for surveillance and reconnaissance. The power supplies are so bulky and heavy that in order to get something big enough to carry the power supply, you no longer have a small, cheap, disposable package. You have something the size of a kid’s remote-control car.”

The MEMS origami technology also could act as microthrusters, propelling microbots over obstacles. “One application we’re working on is very small scale propulsion,” Morris says. “We’re working on making things that can hop or jump to propel themselves. If you have a very, very small system, that’s great for low cost, and it’s easily transportable, but what do you do when it comes to a structure that’s bigger than it is—like a stair step? You may want it to hop up that stair step,” he offers.

Other potential applications include pop-up, reconfigurable radio frequency antennas. “Or, materials would get different signatures bouncing off of them in various radio frequency bands, whether it’s radar or terahertz or even optical,” Morris suggests. “We can cause these things to give different signals back based on what state they’re in, whether they are folded up or folded down and in what way they’re folded. This gets into morphing structures or programmable matter, some of the buzzwords that people use to refer to these sorts of things.”

He adds that the technology might even be used for pixel displays. “It could be useful as a display pixel to essentially wirelessly control a passive display—if you’ve got an array of these things—to switch pixels from one state to another by simply giving them a signal. Think of the digital micromirror projection technology in a lot of digital projectors. That kind of thing could possibly be enabled but without the need for any power supply connected to it,” he says. “I don’t know if this actually has military use, but it would certainly be a fun toy for someone to buy.”

Discussing the pixel display leads Morris to yet another possible application—programmable camouflage. It might be possible to have panel displays with one camouflage pattern that could be “slapped onto” a vehicle. “You could have a panel on a vehicle that has a current camouflage pattern on it, and then you could change that to some other environment,” he theorizes. Thinking it through, however, he concludes that the technology will likely be too costly to cover an entire vehicle. “With smaller areas it’s doable. You’re talking about some of the same manufacturing techniques available in flat-panel displays today. You could get a cell-phone sized display fairly cheaply, but a 60-inch screen is still pretty expensive. What the cost would be to cover a car with fabricated, pixilated display technology, I don’t know. I think it would be rather expensive.”

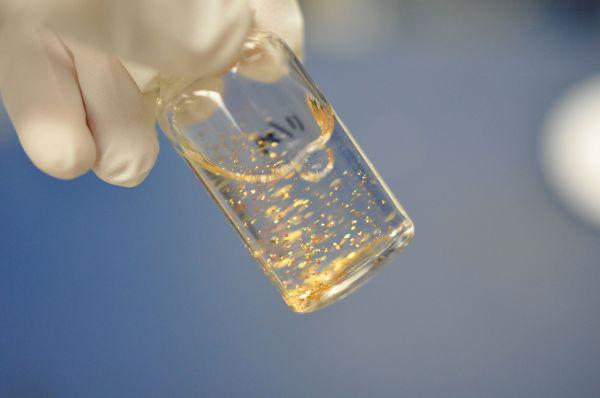

The origami-like structures use a silicon substrate and layers of various metals, such as gold, chrome or copper. Some layers are fabricated to be stressed, while others are in a relaxed state. Depending on how they are made, the structures can be forced to fold either down or up. “If you have a polymer, or thermally sensitive layer, that’s sufficiently thick, it will prevent the layers from folding because you have this other material on top, so it is like a spring that’s compressed,” Morris elaborates. “Then, when we shine the light on it to heat it up, that polymer becomes much more soft and it allows the residually stressed layers to fold.”

Researchers have challenges to overcome to make the technology more feasible. “The way the structures work right now, they can really only be used once. They can fold in one direction one time, so we really want to demonstrate a reversible approach,” Morris reveals. He adds that a new co-sputtering tool in the laboratory should help researchers work out the problem. “This co-sputtering tool is a way to deposit thin films of a mix of materials—specifically, nickel and titanium. If we can atomically mix them in the right ratio, we get a very nice shape memory that will allow us to have snap between different mechanical shapes at right around room temperature. We can make it either right below or right above room temperature by controlling the ratio of nickel and titanium,” he says.

ARL officials also intend to lower the light levels needed to induce the folding action. “We expect to be able to demonstrate what I’ll call low-power optical demonstration, targeting around 300 to 400 milliwatts per centimeter as opposed to about 680, which was the lowest we had before. We’re doing that by incorporating more sensitive optically absorbing materials, which are designed to absorb light more efficiently at the wavelength we’re using,” Morris reveals.

So far, the lighting can be directed at the structures from up to 3 feet away using a handheld laser. Depending on the wavelength and intensity of the laser irradiation, the folding will occur between 67 milliseconds and 21 seconds. Researchers also may be able to reduce the size from micro to nano levels.

The ARL research builds upon the work done by David Gracias at Johns Hopkins University (JHU). Gracias and his team developed the star-shaped MEMS devices to act as microgrippers for non-invasive surgery or biopsies. Because the JHU structures are intended to be used inside the human body, researchers there are more interested in devices that work in a largely liquid environment and intend to use chemicals rather than lasers to trigger the folding response. “The concept is to have these to be used as cancer detectors or to perform biopsies of tissue,” Morris says.

If cancer is giving off a particular protein or chemical signature, for example, it could trigger a response from the MEMS devices. “I saw a video where [Gracias] was able to take these—in the lab anyway—and move these tiny grippers up a little glass capillary tube up to a clump of cells at the end of the tube and have these things grab onto those cells and pull them off, performing a tetherless biopsy simulated in the lab,” Morris reports.

Morris invited Gracias to give a seminar at ARL. Since then one of the students on the JHU team has worked regularly with the Army team.

Morris has referred to the devices as pixie dust, suggesting they could be scattered on the battlefield, going unnoticed by enemy forces, until they are needed, possibly as unattended ground sensors. He confesses, though, that some at ARL are not fond of the pixie dust analogy. “That was my probably rather poor attempt at conveying in layman’s terms the concept of a fully self-contained microsystem that, to the naked eye, may look like a speck of dust or sand, but that could have significant functionality—like a microbotic concept where it could get up and actually move itself somewhere,” he says. “I actually got some flack from my colleagues about that term.”

Comments