Metal Foam Stops Armor-Piercing Bullets

A composite metal foam (CMF) material developed by researchers at North Carolina State University can stop ball and armor-piercing .50 caliber rounds as well as conventional steel armor, even though it weighs less than half as much, the university recently announced. The finding means that vehicle designers will be able to develop lighter military vehicles without sacrificing safety, or can improve protection without making vehicles heavier.

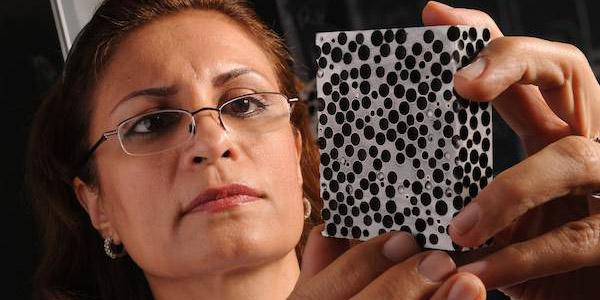

Previous research has resulted in CMF material capable of shredding bullets.

CMF is a foam that consists of hollow, metallic spheres made of materials such as stainless steel or titanium and embedded in a metallic matrix made of steel, titanium, aluminum or other metallic alloys. In this study, the researchers used steel-steel CMF, meaning that both the spheres and the matrix were made of steel.

For the study, researchers manufactured a hard armor system consisting of a ceramic faceplate, a CMF core and a thin back plate made of aluminum. The armor was tested using .50 caliber ball and armor-piercing rounds. The armor was tested with the rounds being fired at impact velocities from 500 meters per second up to 885 meters per second.

The CMF layer of the armor was able to absorb 72 to 75% of the kinetic energy of the ball rounds, and 68 to 78% of the kinetic energy of the armor-piercing rounds.

“The CMF armor was less than half the weight of the rolled homogeneous steel armor needed to achieve the same level of protection,” says Afsaneh Rabiei, corresponding author of a paper on the work and a professor of mechanical and aerospace engineering at North Carolina State University.

“In other words, we were able to achieve significant weight savings—which benefits vehicle performance and fuel efficiency—without sacrificing protection,” says Rabiei, the inventor of CMF who has spent years developing and testing CMF materials.

She adds that the material can be improved further by optimizing adhesion and thickness of the ceramic, CMF and aluminum layers, which may lead to even lower total weight and improved efficiency of the final armor.

Comments